WhatsApp

WhatsApp

The traditional recycling tires technology include burial, incineration, and local refining, which have relatively low economic benefits and can cause secondary pollution. Do you know of any new technology to recycle and process waste tires in an economical and environmentally friendly way?

Pyrolysis plant is a notable technology used for recycling tires. The principle of pyrolysis is to place the tire under oxygen-free and high-temperature conditions, and convert macromolecular organic compounds into gaseous, liquid, and solid components(gas, pyrolysis oil, and carbon black) with relatively low molecular weight. And this new technology allows for the recycling and extraction of valuable materials from tires, while minimizing waste and environmental impact.

DOING tire recycling pyrolysis plant

DOING tire recycling pyrolysis plant

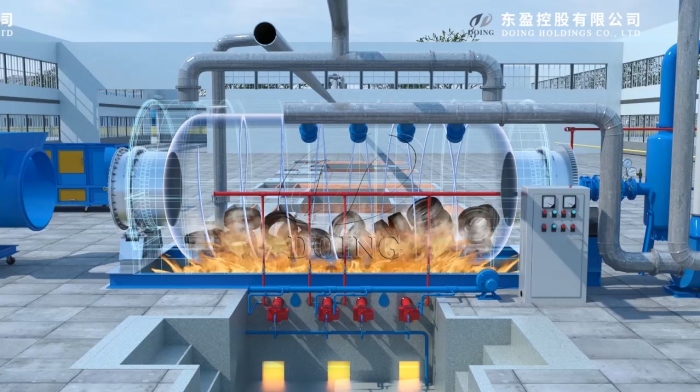

1. Feeding and heating: Waste tires are fed into a reactor where they are heated at high temperatures. As the temperature heats up, they undergo thermal breakdown, converting into oil-gas and carbon black.

(The most suitable temperature for pyrolysis tires is between 280°C and 320°C. During operation, it is necessary to continuously and steadily increase the temperature, which will improve production efficiency and extend the service life of the tire recycling pyrolysis plant.)

The heating process of DOING pyrolysis plant

The heating process of DOING pyrolysis plant

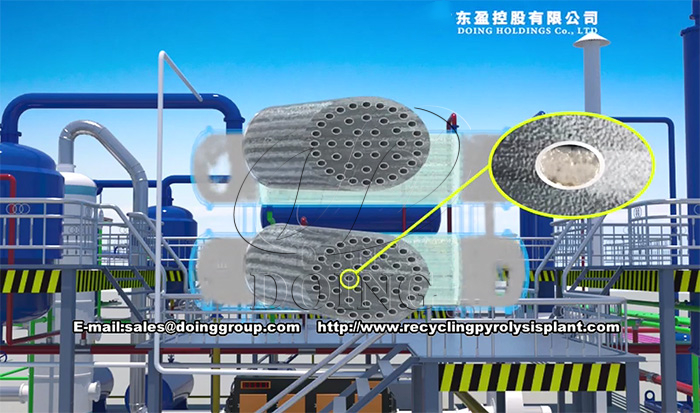

2. Gas and oil separation: After the condensation system, the oil and gas are separated. The tube condensing system consists of some horizontal and vertical condensers. The multi-channel condensing process makes the oil and gas fully condensed and ensures a high oil yield. In addition, our pyrolysis plant is equipped with vacuum negative pressure devices, which not only ensure safety but also shorten the cooling time and improves the oil yield.

3. Solid residue collection: DOING tire recycling pyrolysis plant is equipped with a special carbon black collection system - carbon black hoist, which can collect carbon black in a closed environment without causing dust pollution.

The cooling process of DOING pyrolysis plant

The cooling process of DOING pyrolysis plant

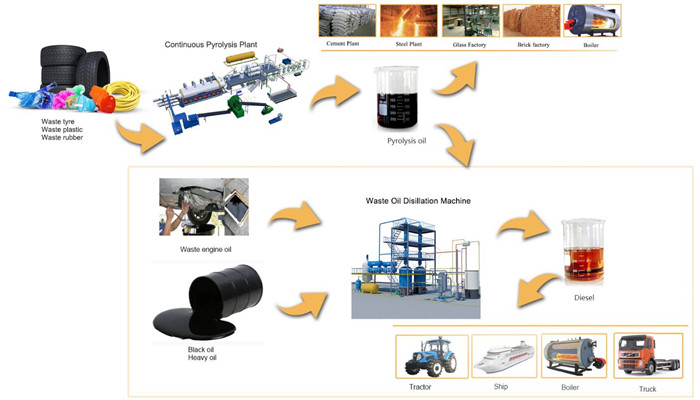

1. The gases can be used for fuel within the pyrolysis plant itself.

2. The pyrolysis oil, which is the most profitable one among them, can be used for boiler heating and sold to steel plants, cement plants, and other industries. In addition, nearly 90% of the pyrolysis oil can be refined to obtain diesel oil by DOING pyrolysis oil refinery plant and generate more profits.

3. Carbon black after deep processing can be used as a raw material in the rubber and plastic industries for manufacturing new products. So deep processing of carbon black can increase the economic income of derivative industries, and facilitate the development of these industries.

The uses of tire recycling pyrolysis products

The uses of tire recycling pyrolysis products

After understanding the waste tire recycling process and the use of pyrolysis products, you will find pyrolysis plant is a more environmentally friendly, safe and economical choice for tires recycling. If you would like to know about our tire recycling pyrolysis plants, please feel free to contact us at any time. Our sales manager will introduce the details of pyrolysis plants to you one-on-one, help you solve problems and provide suitable factory building plans, etc.

contact us

CONTACT US