WhatsApp

WhatsApp

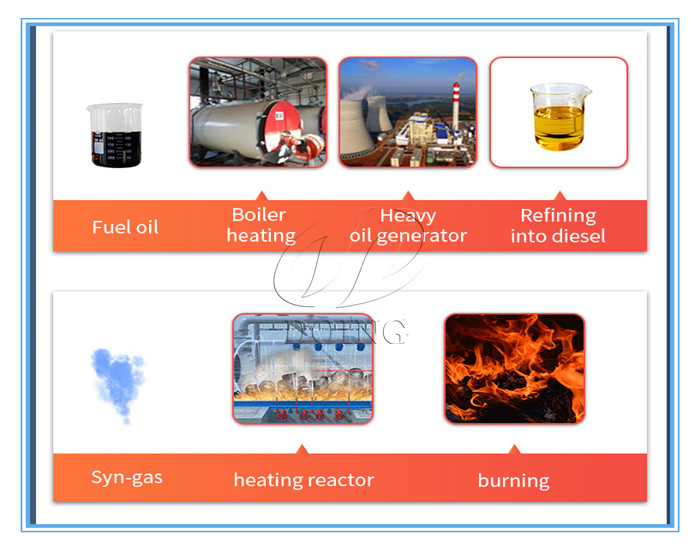

In addition to 45% pyrolysis oil, 30% carbon black and 15% steel wire during the waste tires pyrolysis process, about 10% of exhaust gas will be produced. And this part of exhaust gas produced by waste tire pyrolysis plant can be recycled.

Fuel oil and gas

Fuel oil and gas

This part of the exhaust gas has a high calorific value. After purification, it can not only be used as fuel for heating the pyrolysis reactor, saving fuel, but the excess exhaust gas can also be collected and stored for other industrial heating.

The main components of exhaust gas produced by waste tire pyrolysis plant are hydrogen, CH4, C2H4, C2H6, C3H8 and other non-condensable but highly flammable hydrocarbon gases and a small amount of CO, CO2, H2S. The content of CH4 in gaseous hydrocarbons is relatively high, about 20%~50%, the content of C2H4 is slightly higher, about 10%~20%, and the content of C2H6 is about 6%~12%. As the carbon number increases, the hydrocarbon content gradually decreases, and the CH4 content is the highest at 41.39vol.%. The calorific value of the exhaust gas is 35MJ/m3, which is equivalent to that of natural gas, and has high utilization value.

Exhaust gas can be used for the pyrolysis plant

Exhaust gas can be used for the pyrolysis plant

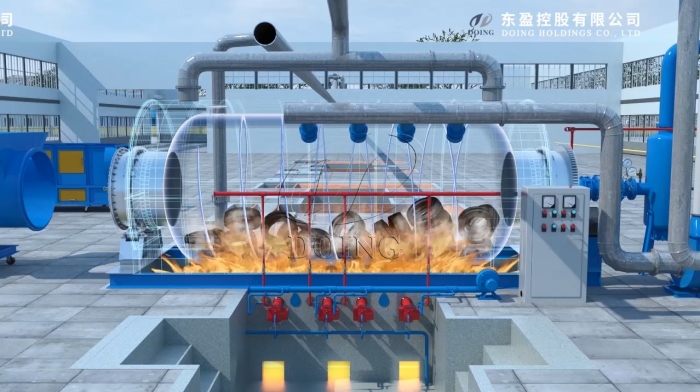

Under normal circumstances, the exhaust gas produced by waste tire pyrolysis plant can be directly recovered and heated to refinery furnaces to save other fuels. However, since the exhaust gas contains a small amount of polluting gases such as H2S, CO, and CO2. Among them, H2S gas is a colorless, flammable acidic gas with a bad odor at low concentrations. If it is directly burned or discharged into the air without treatment, it generally cannot meet the national environmental protection requirements.

Therefore, the exhaust gas produced by waste tire pyrolysis plant needs to undergo specific desulfurization and deodorization treatment before recycling, and then enters the furnace to burn through gas nozzles to heat the waste tire pyrolysis plant reactor, which is energy-saving and environmentally friendly.

The tail gas purification system

The tail gas purification system

DOING Company has specially launched a desulfurization and deodorization tower to deal with the exhaust gas produced by waste tire pyrolysis plant. The desulfurization and deodorization tower is composed of buffer tank, two-stage spray tower and water seal. It can remove H2S gas and help customers solve the problem of bad odor in waste tire pyrolysis plant. In addition, harmful components such as soot, SOx, NOx, and voc produced during the combustion exhaust process will be treated by the flue gas purification system to achieve environmentally friendly emissions requirements.

Henan DOING waste tire pyrolysis plant provides an environmental protection treatment control system, which has corresponding purification treatment for waste smoke, waste gas and odor generated during the pyrolysis process, and meets the environmental protection standards of different countries. Welcome to consult for our green technology waste tire pyrolysis plant!

contact us

CONTACT US