WhatsApp

WhatsApp

Waste tire pyrolysis plant can convert waste tires and rubber into crude oil, which can not only turn waste into treasure, but also reduce environmental pollution, which has been recognized by many countries and regions.

DOING waste tire pyrolysis plant for recycling waste to treasure

DOING waste tire pyrolysis plant for recycling waste to treasure

So what are the common problems and preventive measures for waste tire pyrolysis plant ? DOING company has been doing this kind of business over 10 years, we have summarized the following answers from our experience, please kindly check.

1. Low oil yield

Under normal circumstances, the oil yielding rate of waste tires is 40% to 45%. However, if the temperature is not strictly controlled as required, the oil gas cannot be completely converted into oil, and the tail gas content is greatly increased at the same time, thereby causing waste of resources. Therefore, the operator must strictly control the temperature according to our operation manual.

Pyrolysis reactor is being heated

Pyrolysis reactor is being heated

2. Longer time of pyrolysis

The normal pyrolysis time is about 8 hours, but if the water content of the tire is too high, the pyrolysis time will reach 10 hours or more. Because the water needs to be evaporated in the early stage of pyrolysis, so it would be better if you can dry the raw material before feeding, which can effectively save time.

Wet tires need to be dried before pyrolysis process

Wet tires need to be dried before pyrolysis process

3. Bigger smoke

Our waste tire pyrolysis plant is equipped with dedusting system that can effectively dispose of 99.9% smoke. If there is a large amount of smoke in the pyrolysis process, you may check the condition of your furnace basement if it has a good sealing effect, the smoke does not completely enter the dust collector if your basement has any leakage. At this time, the basement should be modified according to the layout provided by the manufacturer. In addition, the draft fan should be opened before the pyrolysis, and it cannot be directly turned off after the pyrolysis is completed until the reactor is cooled. [ Recommended reading: The pollution control system of DOING waste tyre pyrolysis plant ]

Our dedusting system to clean the toxic gas in the smoke

Our dedusting system to clean the toxic gas in the smoke

4. Unstable of the reactor

Under normal circumstances, this situation does not occur. Unless it is over loaded, overloading will lead the reactor to run unevenly. Therefore, the feed should be strictly in accordance with the requirements and cannot be overloaded.

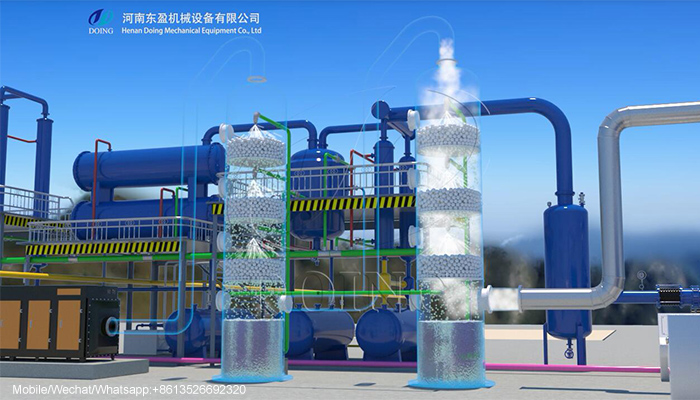

3D drawing of DOING waste tire pyrolysis plant

3D drawing of DOING waste tire pyrolysis plant

The above are the common problems and preventive measures for waste tire pyrolysis plant. If you have other questions, please leave a message on our company website, we will serve you with our professional knowledge.

contact us

CONTACT US