WhatsApp

WhatsApp

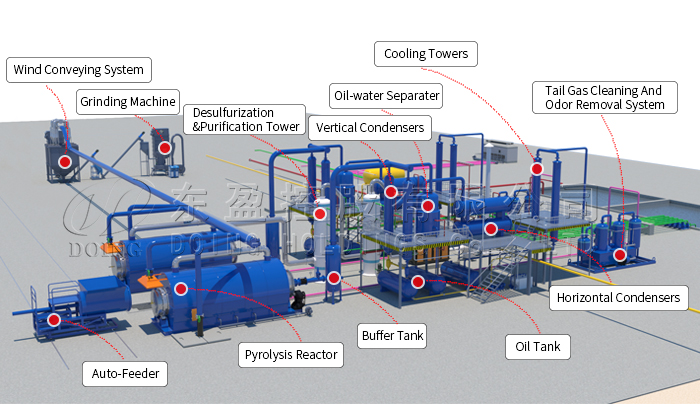

The 3D picture of waste plastic pyrolysis plant

The 3D picture of waste plastic pyrolysis plant

In waste plastics pyrolysis process, the links that are most likely to cause environmental pollution problems are oil gas cooling, exhaust gas emission and carbon black discharge. In this regard, DOING’s waste plastic pyrolysis plant adopts the latest technology to deal with them, aiming to help customers safely pyrolyze waste plastics.

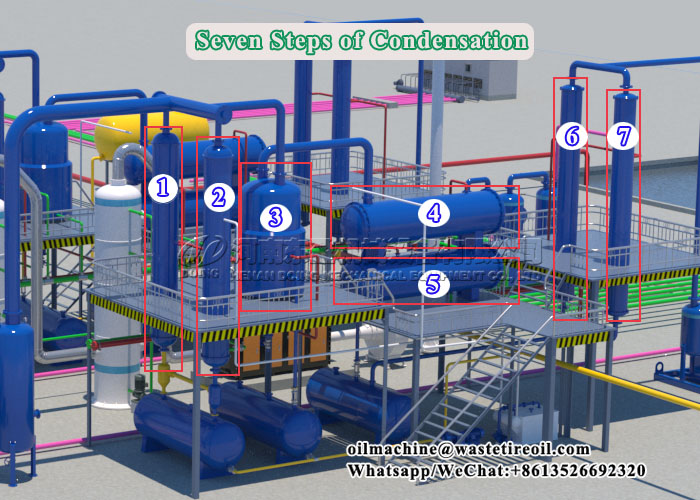

For oil gas cooling, Doing’s waste plastic pyrolysis plant adopts the shell and tube condensers. Cooling water has no contact with oil gas because only goes through between the shell and inner tube for cooling oil gas. This not only ensures the recycling of cooling water and zero discharge of waste water, but also increases the cooling area to make the oil gas are fully cooled.

The seven steps of condensation

The seven steps of condensation

For exhaust gas emission, on one hand, Doing’s waste plastic pyrolysis plant adopts the tails gas cleaning system to recycle combustible gas for reactor heating while remove the smell of the tail gas. On the other hand, Doing also adopts water scrubber and desulfurization tower to desulfurize flue gas generated during the pyrolysis process to achieve environmentally friendly emissions.

Tail gas cleaning system of waste tire pyrolysis plant

Tail gas cleaning system of waste tire pyrolysis plant

For carbon black discharge, Doing’s waste plastic pyrolysis plant adopts wind conveying system to ensure that the whole carbon black discharge process is totally sealed&no dust. The carbon black is removed from the pyrolysis zone, and then transferred to the carbon black temporary storage warehouse by the wind transportation system.

With mature production process design and advanced environmentally friendly waste plastic pyrolysis plant, DOING has helped customers in more than 90 countries around the world to achieve pollution-free pyrolysis of waste plastics. If you also want to join in the waste plastic pyrolysis industry and obtain more profits, please don’t hesitate to consult us and get professional processing solutions&free quotations!

contact us

CONTACT US