WhatsApp

WhatsApp

With the growing environmental concerns around plastic waste, many industries and customers are turning to plastic recycling, which raises the question: can make fuel from plastic? Today, I will answer this question for you. The answer is yes. Both theoretically and practically, it is possible to make fuel from plastic.

Plastic fuel production is a form of chemical recycling that refers to converting waste plastic into a usable energy form, specifically called plastic to fuel (PTF). Unlike producing fossil fuels from raw materials, make fuel from plastic pyrolysis technology breaks down long-chain hydrocarbons in plastics into shorter hydrocarbons – the same components found in traditional fuels.

Plastic-to-fuel (PTF) pyrolysis technology

Plastic-to-fuel (PTF) pyrolysis technology

The following are some simple descriptions of theories and practical methods.

Theoretically possible to make fuel from plastic:

1.Properties of Plastics and Fuels

Most plastics are derived from petrochemical products (crude oil and natural gas), and are composed of long chains of carbon and hydrogen atoms (hydrocarbons). Fuels are mixtures of hydrocarbons, but with much smaller and simpler molecular structures. This makes the conversion of plastics into fuel both scientifically plausible and efficient.

2.Principle of Pyrolysis:

Pyrolysis is a thermal decomposition process known as reversal: its core theory is to reverse the aggregation process. By applying energy (in the form of heat and sometimes pressure), we can break down long polymer chains (depolymerization) back into smaller hydrocarbon molecules that make up the fuel.

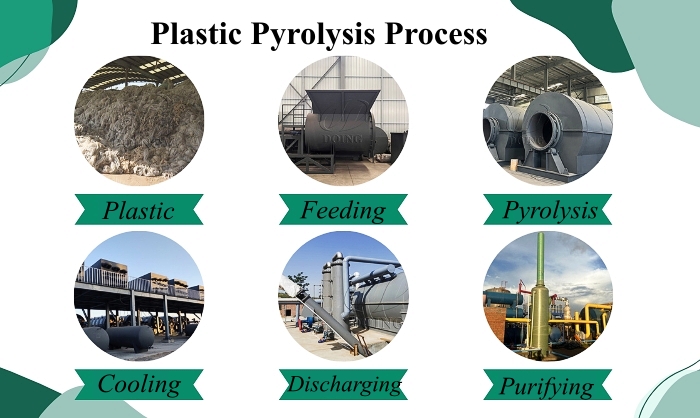

Make fuel from plastic pyrolysis process

Make fuel from plastic pyrolysis process

Practically possible to make fuel from plastic:

1.Environmental Benefits:

Make fuel from plastic not only reduces the environmental burden of landfill and incineration but also reduces dependence on traditional fossil fuels, providing an environmentally friendly alternative.

2.Economic Benefits:

Make fuel from plastic pyrolysis technology provides additional energy source: pyrolysis oil, carbon black and combustible gas, creating economic incentives for the recycling of plastic waste, especially in areas with large waste volumes and high energy demands.

Pyrolysis Oil: A synthetic crude oil that can be directly used for industrial heating, such as in boiler rooms, brick factories, glass factories, gypsum factories, heavy oil generators, etc.. It can also be further refined into diesel fuel for diesel generators, tractors, trucks, ships, and other heavy machinery.

Carbon Black: A carbon-rich solid residue that can be used as a rubber/plastic filler, a metallurgical carbide raw material, an alternative fuel for cement kilns, and building materials.

Synthesis Gas: A mixture of hydrogen, carbon monoxide, and methane, which can be used directly as fuel.

3.Technological Advancements

With continuous advancements in pyrolysis technology, the efficiency and economic feasibility of making fuel from plastic processes are constantly improving. For example, using catalysts can accelerate reaction rates and improve product quality, while optimizing reaction conditions can reduce energy consumption and increase output. Furthermore, large-scale production facilities reduce unit processing costs. DOING distillation equipment can improve the quality of pyrolysis oil, and DOING's anti-coking reactor design can solve problems such as coking and waxing during plastic pyrolysis.

DOING make fuel from plastic pyrolysis machine

DOING make fuel from plastic pyrolysis machine

As a professional environmental protection equipment manufacturer specializing in solid waste recycling for over 14 years, DOING has extensive experience in the recycling of plastic, a complex and diverse raw material. We can move from theoretical feasibility to practical application of making fuel from plastics. Specialized pyrolysis equipment designs and processes can be provided for different plastics to achieve the goal of converting waste into usable energy.

If you still have many questions about this topic or are unsure about how to maximize the benefits from plastic recycling, contact DOING. The business manager will customize the most suitable solution based on your needs.

contact us

CONTACT US