WhatsApp

WhatsApp

Waste oil field sludge, a byproduct of oil and gas exploration and production, presents a significant environmental and economic challenge. Composed of crude oil residues, water, solids, and various contaminants, its disposal is costly and can lead to severe pollution. However, this seemingly problematic waste material holds valuable potential for fuel recovery. So, how do we separate fuel from waste oil field sludge? Here is the oil sludge and fuel seperation solution: pyrolysis machine.

DOING waste oil field sludge pyrolysis plant

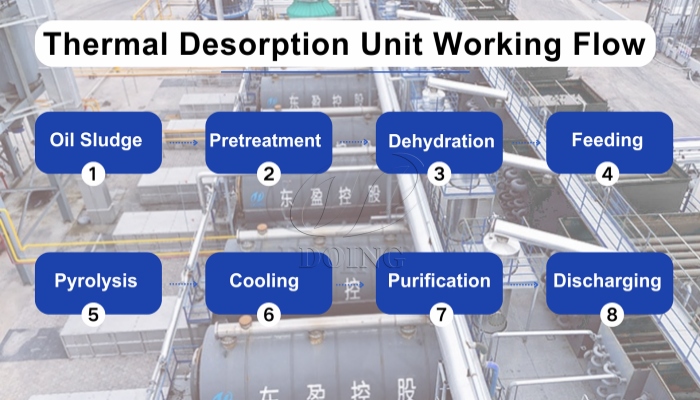

Pyrolysis is a thermochemical process that involves the thermal decomposition of organic materials at elevated temperatures in the absence of oxygen. In the context of waste oil sludge, this process allows us to:

Decompose Complex Hydrocarbons: The heavy hydrocarbons and organic compounds in the sludge are broken down into lighter, more valuable liquid hydrocarbons (pyrolysis oil), combustible gases, and a solid char.

Separate Components: The heat drives off volatile components, effectively separating them from non-volatile solids and water.

Recover Energy: The resulting pyrolysis oil and gas can be used as fuel, offsetting energy consumption in the plant or being sold as a product.

Waste oil field sludge pyrolysis plant products

Pre-treatment: For highly viscous or solid sludge, initial steps like shredding or dewatering mixing may be employed to facilitate feeding.

Feeding: Sludge is introduced into the reactor. For liquid sludge, this is via a robust pumping system. For semi-solid or solid sludge, screw feeders are often utilized.

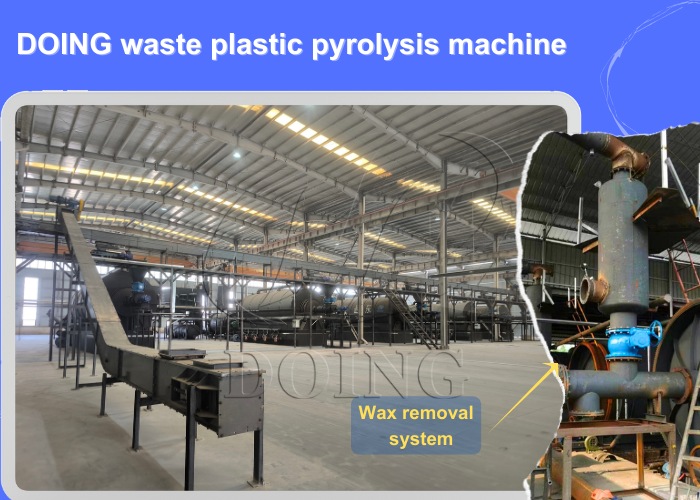

Pyrolysis Reaction: The material is heated in the oxygen-free reactor. The specialized wax removal system actively manages any wax formation.

Gas and Oil Collection: Volatile gases and oil vapors rise and are channeled through a cooling system.

Oil Condensation: The vapors condense into pyrolysis oil, which is collected.

Syngas Utilization: Non-condensable gases (syngas) are typically used to fuel the pyrolysis process itself, enhancing energy efficiency.

Char Discharge: The solid residue (char/carbon black) is safely discharged from the reactor.

This pyrolysis process effectively separates the hydrocarbon-rich fuel components from the water and inert solids.

DOING waste oil sludge pyrolysis plant working flow

Before offer oil sludge and fuel separation pyrolysis machine solution, we Henan Doing Company will learn about the situation of oil sludge materials. Oil field sludge is not a monolithic substance; its composition and physical state can vary considerably. We typically categorize it into three main types, each requiring a tailored approach for optimal processing:

Liquid Sludge: Characterized by high water and oil content, with a low viscosity.

Solid Sludge: Contains a higher proportion of solids and a lower percentage of oil and water, often appearing as a more viscous or semi-solid mass.

Semi-Solid/Half Liquid Sludge: A mixed state, exhibiting properties of both liquid and solid sludge, often with a thick, paste-like consistency.

Furthermore, the oil content within the sludge is a critical factor influencing the choice of processing technology and machine configuration. Higher oil content means greater potential for fuel recovery but also introduces unique processing challenges.

Recognizing the diverse nature of oil field sludge, DOING offers highly adaptable pyrolysis plant configurations:

For Liquid Oil Sludge: We recommend our semi-continuous pyrolysis plant. Given its liquid nature, this sludge can be efficiently introduced into the pyrolysis reactor via a dedicated pump feeding system. This automated approach ensures consistent and safe material handling.

DOING oil field sludge semi-continuous pyrolysis plant

For Solid and Semi-Solid Sludge: Depending on the degree of solidification and viscosity, we may recommend modifications to the feeding system (e.g., screw feeders) or pre-treatment steps to ensure optimal material flow into the reactor. The core pyrolysis technology remains highly effective across these variations.

Addressing Wax Accumulation: A significant challenge with high-oil-content sludge is the potential for wax to solidify and accumulate at the bottom of the reactor during the heating process, hindering operation. To overcome this, our reactor is equipped with a specialized wax removal device. This innovative feature continuously extracts or liquefies any generated wax, preventing blockages and ensuring uninterrupted, high-efficiency operation.

DOING pyrolysis plant wax removal system

Significant Fuel Recovery: Transform a waste liability into a valuable energy asset. The recovered pyrolysis oil can be used as industrial fuel blended with conventional fuels, or further refined.

Environmental Compliance: Dramatically reduce the volume of hazardous waste requiring disposal, lowering environmental impact and meeting stringent regulatory requirements.

Economic Viability: Offers a cost-effective alternative to traditional oil field sludge disposal methods, while generating revenue from recovered fuels.

Reduced Operational Costs: The self-heating capability using syngas minimizes external energy input.

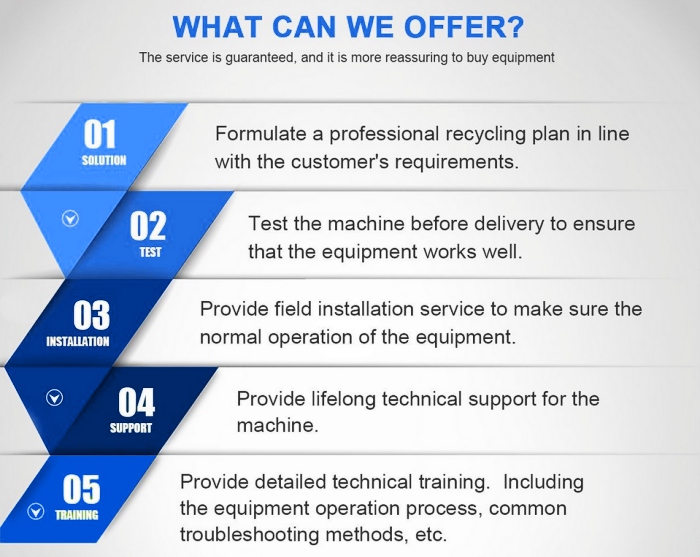

Tailored Configuration: We don't offer a one-size-fits-all solution. We analyze your specific sludge composition (oil content, moisture, solid impurities) to recommend the optimal configuration, which may include pre-treatment systems like drying and shredding for solid sludge.

Waste oil field sludge is not just a disposal problem, it is a valuable resource waiting to be unlocked. DOING Company's pyrolysis plant provides a proven, efficient, and environmentally sound solution for separating fuel from oil field sludge. With DOING's specialized designs, particularly the innovative wax removal system for liquid sludge, we help transform waste oil field sludge into a valuable fuel resource.

DOING oil field sludge pyrolysis plant manufacturer

If you are seeking an effective method to separate valuable fuel from waste oil field sludge, we invite you to learn more about our pyrolysis technology. We invite you to explore the possibilities further.

Please contact us to:

Receive detailed technical specifications and case studies.

Discuss your specific oil sludge processing needs with our salesman.

Arrange a consultation or virtual plant tour.

Inquire about a customized project proposal.

contact us

CONTACT US