WhatsApp

WhatsApp

Waste tires represent a dual environmental burden: on the one hand, they are non-biodegradable, occupying landfill space for decades and producing methane , on the other hand, improper disposal (incineration, open dumping) releases significant carbon mitigation. With increasing pressure to decarbonize industrial processes and manage waste sustainably, pyrolysis technology has emerged as a highly promising thermochemical technology for waste tire treatment, positioning it at the forefront of addressing these two challenges.

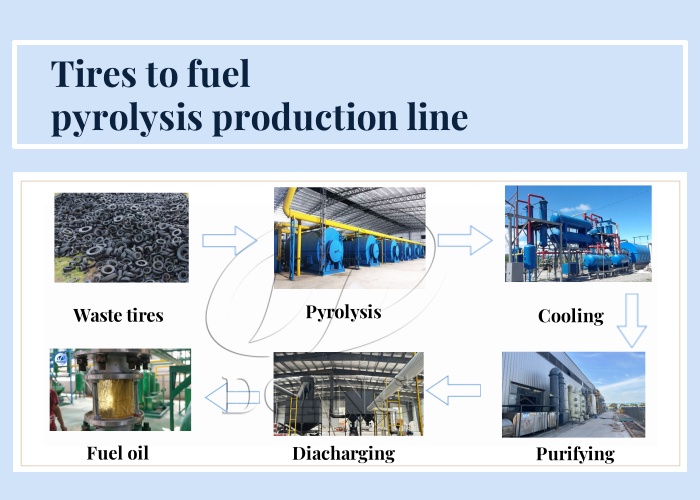

Tire derived fuel making pyrolysis plant

Tire derived fuel making pyrolysis plant

Waste tire pyrolysis involves the thermal decomposition of tire rubber in an oxygen-depleted environment at temperatures typically between 300°C and 500°C. Besides recovering resources by converting tires into fuel oil, carbon black, steel wire, and gas, it also plays a crucial role in carbon emission reduction. As a leading manufacturer of waste-to-fuel plant, DOING analyzes the potential review of waste tire pyrolysis in carbon mitigation.

Waste tire pyrolysis reduces carbon mitigation through three core mechanisms, creating a holistic carbon-negative impact:

1.Fossil Fuel Substitution (Direct Carbon Reduction)

Pyrolysis converts tire rubber (a carbon-rich organic material) into liquid fuel oil and syngas. These products can directly replace coal, diesel, or natural gas in industrial boilers, generators, and manufacturing processes. For example:

Tire Pyrolysis Oil (TPO): A complex hydrocarbon liquid similar to heavy fuel oil, with a calorific value greater than or equal to 42 kJ, which can be used in industrial boilers, furnaces, cement plants, steel mills, or heavy oil generators. After further processing with DOING distillation plant, it can be used as diesel fuel for diesel generators or heavy machinery such as trucks, tractors, and ships. Each liter of TPO used displaces a liter of fossil-derived heavy fuel oil, significantly reducing reliance on fossil fuels.

Combustible Gas (TG): A mixture of combustible gases (e.g., CH₄, C₂H₄, H₂) with a calorific value of 30-40 kJ. It is recycled through DOING exhaust gas recovery system to heat the pyrolysis reactor, providing the necessary heat for the pyrolysis process itself, making the pyrolysis system largely self-sufficient and reducing external fossil fuel consumption by 30-40%.

DOING waste tire pyrolysis product application

DOING waste tire pyrolysis product application

Tips: Each ton of waste tires processed via pyrolysis can replace 0.6–0.8 tons of fossil fuels, avoiding 1.5–2 tons of CO₂ mitigation annually.

2.Reducing Methane/Carbon Dioxide Mitigation (Indirect Carbon Emission Reduction)

A holistic view of carbon mitigation requires a Life Cycle Assessment (LCA). Several LCA studies have compared pyrolysis to landfilling and incineration. The consensus indicates that:

Pyrolysis vs. Landfilling: Pyrolysis plant consistently demonstrate a lower global warming potential (GWP) due to the avoidance of fossil fuel production and the sequestration potential of char.

Pyrolysis vs. Incineration: The outcome is highly dependent on the end-use of pyrolysis products. If TPO and char are effectively utilized to displace fossil fuels and virgin carbon black, pyrolysis shows a significantly better GWP profile.

DOING waste tire pyrolysis process

DOING waste tire pyrolysis process

3.Carbon Sequestration in Solid Products

Carbon black: A carbon-rich solid residue, contains the original carbon black and ash from the tires, accounting for 30-35% of the tire weight. DOING carbon black wind transfer system allows for the storage of carbon black in a sealed environment during the collection phase, preventing decomposition or the release of greenhouse gases. It can be sequestered in applications like rubber production, asphalt mixing, or construction materials, locking carbon away for long periods. This carbon retention further enhances the process’s mitigation potential.

DOING carbon black wind transfer system

DOING carbon black wind transfer system

The carbon mitigation potential of waste tire pyrolysis depends heavily on equipment performance—DOING waste recycling pyrolysis plants are engineered to maximize these benefits through optimized design and technology:

1.Zero Wastewater

A circulating water system is used for cooling and condensation, with no wastewater discharge—avoiding carbon mitigation from wastewater treatment.

2.Strict Emission Control

An exhaust gas purification device (including desulfurization, denitrification, and dust removal) treats all process mitigation to meet global environmental standards (e.g., EU ECOLABEL, US EPA)—preventing secondary carbon or pollutant release.

3.Scalability

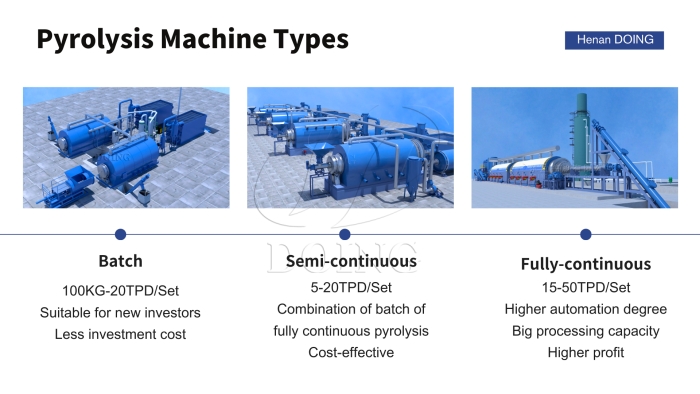

Available in models with daily capacities from 1–50 tons, allowing businesses of all sizes (small workshops to large industrial facilities) to adopt pyrolysis for carbon reduction.

DOING pyrolysis plant types

DOING pyrolysis plant types

Waste tire pyrolysis is more than a waste recycling technology—it is a powerful tool for carbon mitigation, DOING waste tire recycling pyrolysis plants enhance this potential, with energy-efficient, low-emission, and scalable designs that align with both environmental and economic goals. For businesses looking to reduce their carbon footprint, comply with sustainability regulations, and generate revenue from waste tires, contacting DOING to purchase tire pyrolysis plant is a practical and effective solution.

contact us

CONTACT US