WhatsApp

WhatsApp

Oil sludge is an unavoidable by-product of the petroleum industry's extraction, transportation, and refining processes. It is a complex mixture of petroleum hydrocarbons, water, and solid minerals. As the demand for oil grows, so does the amount of oil field sludge and tank sludge produced each year. Both oil field sludge and tank sludge are rich in toxic substances ranging from the most carcinogenic polycyclic aromatic hydrocarbons (PAHs) to heavy metals and even radioactive substances. Most of them pose potential risks to human health and the environment.

Currently, the most common methods of disposal of oil sludge are immobilization and landfill, which require a lot of space and pose a serious threat to the soil and groundwater environment. In fact, oil sludge is also a potential resource for recycling due to its high heating value. Therefore, converting the stored energy of oil sludge into various fuel sources for power plants or engines has been considered as an attractive approach. For this purpose, we have developed oil sludge pyrolysis unit which can turn oil sludge into fuel oil, solid and water.

DOING oil sludge pyrolysis unit

DOING oil sludge pyrolysis unit

The introduction of DOING oil sludge pyrolysis unit

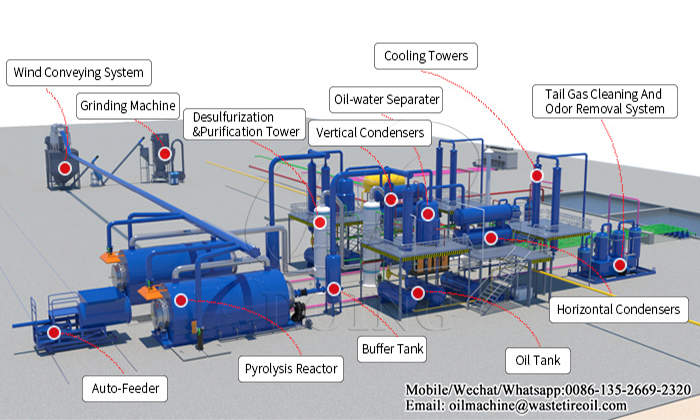

Our DOING oil sludge pyrolysis unit adopts the most advanced thermal pyrolysis technology which includes main components such as screw feeder, reactor, buffer chamber, condenser, oil-water separator, water seal device, oil tank, dust removal system, vacuum system, exhaust gas purification system, tail gas combustion device, etc. Our oil sludge pyrolysis unit is also equipped with special environment protection devices for treating all waste water and waste gases, which does not pollute the environment.

The components of DOING oil sludge pyrolysis unit

The components of DOING oil sludge pyrolysis unit

The advantage of DOING oil sludge pyrolysis unit

1.The rotating reactor can be heated evenly in 360°. In this way, it will not heat only one part of the reactor for a long time, thus making the reactor more durable.

2.Equipped with a three-stage condensing system, DOING oil sludge pyrolysis unit has a high oil yield and high oil quality, and the fuel oil can be sold directly as a commercial product.

3.The negative pressure device operates through water circulation, greatly increasing the safety of the system.

4.Equipped with environmental protection purification equipment, the treatment of flue gas, exhaust gas and waste gas meets environmental protection requirements.

In order to meet the different requirements of our customers, we have designed different capacities of oil sludge pyrolysis unit. The following are the specific parameters of the unit for your reference. In addition, DOING can customize the oil sludge pyrolysis unit according to your situation.

| Technical parameter of oil sludge pyrolysis unit | ||||

| Items | Contents | |||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | Waste tyre | Waste tyre | Waste tyre |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

When the whole pyrolysis process is over, you can obtain three final products: fuel oil, soil and water from the oil sludge pyrolysis unit. And these products can be used in different areas for different purposes.

The products of oil sludge pyrolysis unit

The products of oil sludge pyrolysis unit

1. Fuel oil. The fuel oil is of high quality and can be used directly as fuel. In addition, it can also be taken to a diesel plant to be refined into diesel.

2. Soil. Not quite the same as ordinary soil, it can be used as a building material or paving material.

3. Water. The water produced is not polluting to the environment after treatment and can be discharged directly.

If you also want to invest in an oil sludge pyrolysis unit to treat oil sludge, please send us an inquiry. We will reply within 24 hours!

contact us

CONTACT US