WhatsApp

WhatsApp

This 3D video completely demonstrates the entire working process of semi-continuous tire pyrolysis plant newly designed by Henan Doing Company. The main working flow of semi-continuous tire pyrolysis plant includes: sealed feeding, preheating reactor, high temperature pyrolysis, oil gas condensation, carbon black discharging, exhaust gas and flue gas purification, etc.

The entire operation process of semi-continuous tire pyrolysis plant is equipped with intelligent mechanical equipment, which can complete semi-continuous production operations. The equipment has a high degree of automation, stable operating conditions, and is clean and environmentally friendly.

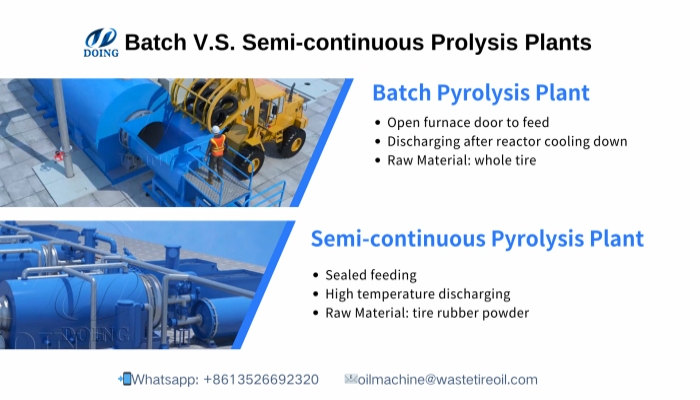

To put it simply, the process flow of semi-continuous tire pyrolysis plant is very similar to that of batch pyrolysis plant. The difference lies in the feeding and slag discharge methods.

Batch pyrolysis plant V.S. semi-continuous pyrolysis plant

Batch pyrolysis plant V.S. semi-continuous pyrolysis plant

Batch tire pyrolysis plant needs to open the furnace door to feed materials. Before discharging carbon black, the temperature of the pyrolysis reactor must be cooled to the required temperature, which is generally required to be lower than 50°C. The semi-continuous tire pyrolysis plant has been upgraded on its basis to achieve sealed feeding and high-temperature slag discharging. It can realize one-stop feeding and slag discharging operations without opening the furnace door, which not only improves production efficiency, but also realizes three times of pyrolysis process in two days. In addition, the sealed pyrolysis process ensures the cleanliness and environmental protection of the running site of pyrolysis plant, and the equipment safety factor is also significantly improved.

To learn more about the differences in process flow, equipment configuration, specifications, equipment prices, etc. between batch tire pyrolysis plant, semi-continuous and continuous tire pyrolysis plants, please leave a message or whatsapp us for consultation. Henan Doing Company is here to serve you wholeheartedly.

contact us

CONTACT US