WhatsApp

WhatsApp

As its name implies, the function of cooling system must be for heat exchanging, which help reduce the temperature of the object to be cooled down. In a similar way, the function of the cooling system of the waste tire recycling plant is mainly for cooling down the pyrolysis oil gas into fuel oil, because the final product cannot be in a gas condition and it needs to be oil with the help of the cooling system.

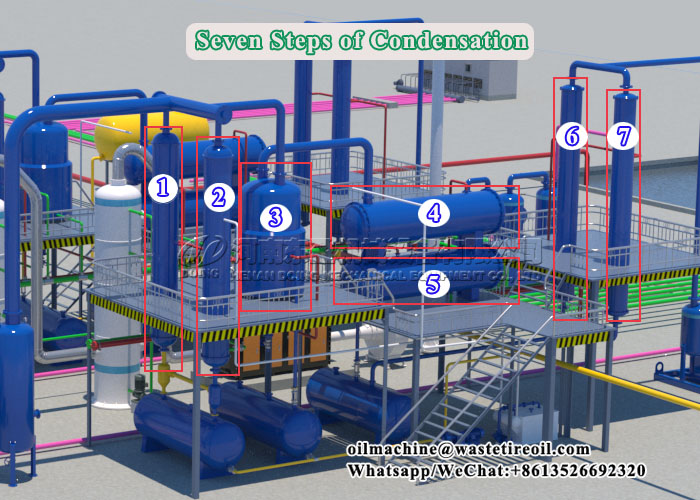

The 3D picture of cooling system

The 3D picture of cooling system

DOING’s waste tire recycling plant adopts 4-step cooling with different functions and each step cooling uses an independent cooling water circulation system to fully guarantee the cooling effect, and then ensure the oil yield.

Following is about the general function of our 4-step cooling system.

1.The function of the 1st step cooling of our waste tire recycling plant

The 1st cooling adopts two vertical cooling condenser. The vertical structure can avoid the accumulation of oily impurities on the top of cooling pipe and then well prevent gas jam.

2.The function of the 2nd step cooling of our waste tire recycling plant

The 2nd step cooling is the oil-water separator. Its structure is like a water seal but outside with water cooling cover, which not only plays the role of oil gas cooling but also functions as the first safety device-water seal in the whole cooling system to prevent the back-flow of oil gas, and also wash off the pyrolysis carbon black powder mixed with the gas in the late pyrolysis stage, so that the gas can be as clean as possible before it flowing into the 3rd step cooling system.

Oil-water separator of waste tire pyrolysis plant

Oil-water separator of waste tire pyrolysis plant

3.The function of the 3rd step cooling of our waste tire recycling plant

The 3rd step cooling adopts two big horizontal tube condensers. With big heating exchange areas, it can thoroughly cooling down all of the oil gas and ensure high oil output.

The horizontal tube condensers

The horizontal tube condensers

4. The function of the 4th step cooling of our waste tire recycling plant

The 4th step cooling is added to cooling down the oil gas that may exist in the dry syn-gas, which can reduce the amount the exhaust gas and ensure oil output.

It is worth mentioning that DOING’s waste tire recycling plant cooling system uses circulating cooling water to ensure zero waste water discharge during the production process. If you also want to recycle waste tire safely and environmentally friendly, welcome to contact us and our engineer team will customize excellent waste tire recycling plant according to your requirements to help you maximize the profits!

contact us

CONTACT US