WhatsApp

WhatsApp

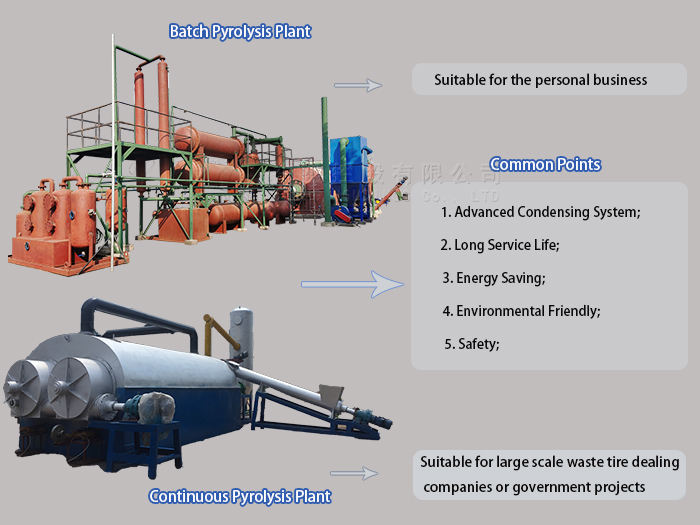

There are mainly two types of pyrolysis plant in the market, one is batch pyrolysis plant, and the other is continuous pyrolysis plant. Many customers noticed these two types pyrolysis plant, but don't know much about the similarities and differences. So here DOING lists the similarities and differences of batch and continuous pyrolysis plant for customers to distinguish them.

The similarity and difference of batch and continuous pyrolysis plant

The similarity and difference of batch and continuous pyrolysis plant

Firstly, let’s talk about the similarities of these two types pyrolysis plant. Whether batch or continuous pyrolysis plant, the working principle of them is the same. Both of them adopts pyrolysis principle to extract fuel oil from waste tires or plastic. And the amount of oil produced from the same raw material is similar.

And then what is the difference of batch and continuous pyrolysis plant? It is mainly reflected in the following two aspects.

①Automation degree

For continuous waste tire pyrolysis device, as the name implies, it can work continuously, such as continuous feeding, continuous oil production, continuous carbon black slagging, no need to stop reactor cooling and carbon black slagging, can work continuously for a month.

For batch pyrolysis technology, the process is feeding, heating start-up, oil production, reactor cooling, carbon black slagging, and finally steel wire removal from the reactor(tire as raw material). Batch waste tire pyrolysis plant should stop operation once to complete batch operation, another process begins after the end of the previous process.

Continuous waste tire pyrolysis plant

Continuous waste tire pyrolysis plant

②Feedstock form

For continuous waste tire pyrolysis plant, the feedstock tires, such as rubber and plastics should be as clean as possible. Besides that, the tires should be crushed and be pressed into 10 mesh rubber powder. And all steel wires in tires should be removed to ensure smooth feeding and unloading and to maintain continuous operation.

But for batch type, the whole tire can enter the reactor without cutting, and the waste plastic can enter the reactor directly without cleaning and selection. Batch waste pyrolysis plants are not picky about the form of feedstock.

After comparison, we can find that the batch pyrolysis plant and continuous pyrolysis plant have their own characteristics. No matter what type pyrolysis plant you want to choose, DOING company can customize it according to your capacity and investment budget. And we can also offer the pyrolysis plant pictures, running videos, free quotations and factory prototypes visiting services for you!

contact us

CONTACT US