WhatsApp

WhatsApp

Henan Doing Environmental Protection Technology Co., Ltd

Leading Waste to Fuel Machine Manufacturer, Supplier & Exporter

Henan Doing Environmental Protection Technology Co., Ltd

Leading Waste to Fuel Machine Manufacturer, Supplier & Exporter

The engine oil purification machine is specially designed for refining waste engine oil. Through the refining equipment, the black heavy engine oil is refined into clean, bright-colored diesel. It is a great way to save resources and energy for our world, while, at the same time, reaping a huge profit. Because of the catalytic distillation method we use, the engine oil purification machine is also called waste oil distillation machine.

Used oil distillation machine in the engine oil refinery plant

Used oil distillation machine in the engine oil refinery plant

The working process of the oil purification machine

1. Preheating

The engine oil purification machine uses two heating systems, one is to heat the distillation reactor with heat transfer oil. The engine oil purification machine needs to preheat the heat transfer oil for a certain period of time before starting up.

2. Distilling

Heat the reactor with heat transfer oil and a burner at the same time. In a high temperature and oxygen-free environment, the distillation reactor will produce oil and gas after reaching a certain temperature.

3. Cooling

The heavier oil and gas are purified by the catalytic tower, the purified oil and gas are cooled into liquefied oil through the condenser and stored in the fraction tank.

4. Purifying

The non-condensable oil and gas in the condensing system is purified by a water seal and used as fuel to heat the distillation reactor.

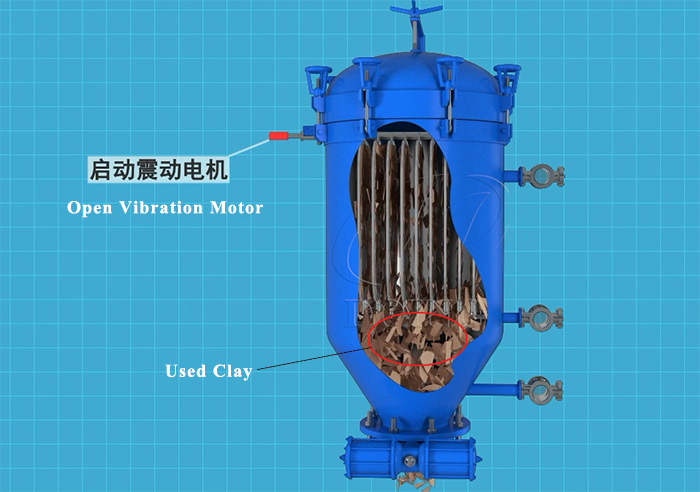

5. Decolorization and deodorization

Used engine oil filter machine

Used engine oil filter machine

Feed the oil in the oil tank into the decolorizing pot, the white clay is added to stir to decolorize, and then the oil fully mixed with the white clay is pumped into the leaf filter to obtain a clear color oil, which is then finely filtered to remove impurities. You can get clean, bright non-standard diesel.

6. Flue gas treatment

The flue gas produced by the heat-conducting oil furnace and the reactor is processed by the desulfurization tower and discharged into the atmosphere after meeting the national emission standards.

The advantages of engine oil purification machine

1. The rapid heating system of the engine oil purification machine uses the heat-conducting oil and the burner to heat at the same time. On the one hand, it can save fuel, on the other hand, it can improve the production efficiency.

2. The oil output rate of the engine oil purification machine can reach 80%-85%, and the obtained oil is fully purified, the oil quality is good.

3. Each reactor of the engine oil purification machine has a thermometer and a safety valve, which is not only convenient for operation, but also safe.

4. The entire refining process is well sealed to prevent gas leakage. And after the exhaust gas is processed, it meets the national emission standards.

5. The reactor adopts a vertical design, which is convenient for slagging, easy to clean, and significant economic benefits.

6. The reactor adopts indirect heating method, which can be evenly and effectively heated and prolong the life of the reactor.

The uses of products from oil purification machines

After the engine oil is purified, you can obtain diesel oil and asphalt. Both of these products have a wide range of uses and markets.

Diesel can be used in diesel combustion engines, generators, heavy machinery and agricultural machinery, it has the environmental protection characteristics of low energy consumption and low pollution. Asphalt can be used directly for road paving or sold to an asphalt plant for refining.

Doing Company specializes in manufacturing waste tires, plastic pyrolysis plant, waste oil distillation machine and other refining equipments. More than ten years of technology precipitation has given us strong research capabilities and equipment manufacturing capabilities. We have been continuously providing customers from all over the world with various equipments. If you want to cooperate with us, please feel free to contact us.

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

Engine oil purification machine

Engine oil purification machine

Advanced Waste Oil Distillation Plant for Sale

Advanced Waste Oil Distillation Plant for Sale

Tyre/Plastic/Rubber fuel oil to diesel oil project report

Tyre/Plastic/Rubber fuel oil to diesel oil project report

Plastic to diesel process plant

Plastic to diesel process plant

Tyre Pyrolysis Oil to Diesel Distillation Plant

Tyre Pyrolysis Oil to Diesel Distillation Plant

Used lube oil refining plant for sale

Used lube oil refining plant for sale

Diesel oil made from crude oil working process

Diesel oil made from crude oil working process

Waste plastic to diesel process machine

Waste plastic to diesel process machine

Plastic to diesel converter plant

Plastic to diesel converter plant

Waste plastic to diesel and gasoline plant

Waste plastic to diesel and gasoline plant