WhatsApp

WhatsApp

Waste plastic to fuel machine can convert waste plastic into fuel oil and carbon black environmentally friendly. It adopts advanced pyrolysis technology, which is a chemical process of thermal decomposition of waste plastics at high temperatures without oxygen. Doing waste plastic to fuel machine has a long service life and high oil yield and is also equipped with high quality environmentally friendly devices to ensure no harm to the environment.

Doing waste plastic to fuel machine

Doing waste plastic to fuel machine

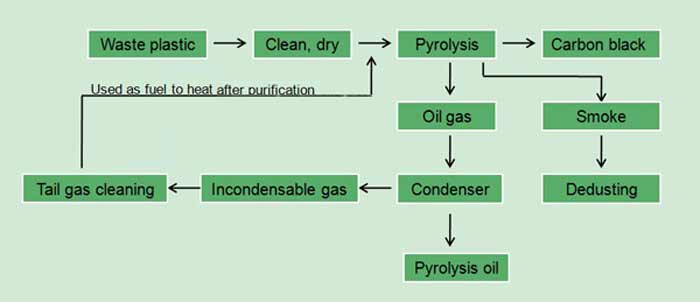

Now let’s take a look at the detailed process of waste plastic to fuel machine.

The process of waste plastic to fuel machine

The process of waste plastic to fuel machine

First, feed waste plastic into the reactor via a conveyor belt. Note that if the waste plastic is wet, you need to dry it first, or it will influence the oil yield.

Then, heat the pyrolysis reactor with fuel, such as coal, gas, wood, oil, etc. When the reactor reaches a certain temperature, the waste plastic in the reactor is transformed into vapor.

The vapor is then transported to a condensing system where it is cooled to liquid fuel oil and collected in a oil tank.

Some of the combustible gas cannot be cooled to liquid and will be recycled to the furnace to assist in heating the reactor, which can reduce fuel consumption for customers.

And during the operation of the waste plastic to fuel machine, some smoke will be generated, which will be treated by the desulfurization and purification tower to reach the environmental protection standard and then it is discharged into the atmosphere.

Finally, when the waste plastic is fully pyrolyzed, the heating of the reactor is stopped and then the carbon black can be discharged when the temperature of the reactor drops to about 50 degrees Celsius.

Our Service & Guarantee

1. Provide turnkey solutions for waste plastic to fuel projects;

2. Responsible for installation and commissioning, staff training;

3. Customized each project according to customer's market, so that to build the most appropriate plan for waste plastic to fuel production;

4. Complete set of after-sales service;

5. We can guarantee the low energy consumption in the process of waste plastic to fuel machine.

Now we have several best-selling models of waste plastic to fuel machine for sale, of which the daily capacity ranges from 500kg to 20 tons. Here are the parameters of the commonly sold models for your reference.

| Technical parameter of waste plastic to fuel machine | ||||

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | Waste plastic | Waste plastic | Waste plastic |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

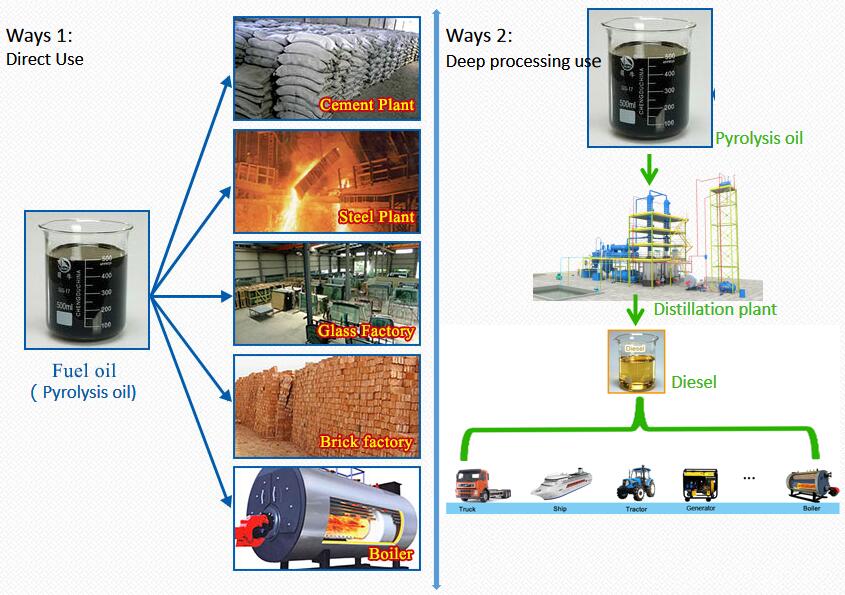

Applications of End Product of Plastic to Fuel Machine

Plastic fuel oil, as the end product of waste plastic to fuel machines, has a wide range of applications.

You can sell this fuel oil directly in the market. It can be ordered by many industrial factories, such as glass factories, cement factories, steel factories, brick factories and so on.

Moreover, you can use our plastic oil to diesel distillation machine to refine the plastic fuel oil into diesel to get a better fuel.

The applications of fuel oil of waste plastic to fuel machine

The applications of fuel oil of waste plastic to fuel machine

If you want to get more information about waste plastic to fuel machine or plastic oil to diesel distillation plant, please contact us directly.

contact us

CONTACT US