WhatsApp

WhatsApp

Through continuous improvement and constant technology upgrading, Doing group has designed the continuous automatic recycling tyre oil plant which can convert tyre into useful resources more efficiently. This continuous automatic recycling tyre oil plant includes DY-30, DY-50 and DY-80 and its the daily processing capacities range from 30 to 80 tons.

Continuous automatic recycling tyre oil plant

Continuous automatic recycling tyre oil plant

Continuous automaic recycling tyre oil plant working process:

Continuous automaic recycling tyre oil plant working process

Continuous automaic recycling tyre oil plant working process

a. Before feeding waste tyres into our continuous automatic recycling tyre oil plant, use steel wire pulling machine to separate the steel wire out of the waste tyres, then cut the left tyres into tyre pieces by the tyre shredder. The tyre pieces will be used as raw material for our continuous waste tire pyrolysis plant. The steel wire got from the waste tyres can be packaged and sold directly.

b. Turn on the auto-feeder, small tire pieces loaded into reactor.

c. Heating the pyrolysis reactor, when it reaches certain temperature the gas oil is generated from the waste tire.

d. Oil gas is generated and condensed into fuel oil to be stored, sync gas is recycled and used as fuel during operation; at the same time, carbon black is also discharged from the auto-discharge system.

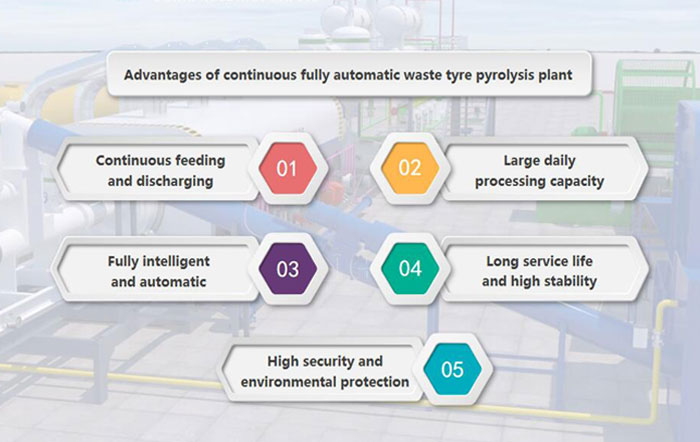

Continuous automatic recycling tyre oil plant advantages:

Continuous automaic recycling tyre oil plant advantages

Continuous automaic recycling tyre oil plant advantages

1. Feeding and discharging in every seond and minute

2. Large daily processing capacities

3. Production efficiency

4. Durable, prolong life

5. Safe operation, environmental protection

Continuous automatic recycling tyre oil plant

| No. | Item | Specifications | ||||||

| 1 | Model | DY-C-10 | DY-C-20 | DY-C-30 | DY-C-50 | DY-C-60 | DY-C-80 | DY-C-100 |

| 2 | Cpacity | 10T/D | 20T/D | 30T/D | 50T/D | 60T/D | 80T/D | 100T/D |

| 3 | Power | 35Kw | 50Kw | 65Kw | 80Kw | 90Kw | 105Kw | 120Kw |

| 4 | Working type | Continuous | ||||||

| 5 | Reactor deisgn | Mutiple reactors (The quantity and size depends on the raw material condition) | ||||||

| 6 | Rotating | Internal rotating | ||||||

| 7 | Cooling system | Recycled waster cooling | ||||||

| 8 | Reactor material | Q245R/Q345R boiler plate | ||||||

| 9 | Heating method | Indireact hot air heating | ||||||

| 10 | Heating fuel | Fuel oil/gas | ||||||

| 11 | Feedstock | Waste tire/plastic/rubber | ||||||

| 12 | Output | Fuel oil, carbon black | ||||||

The applications of continuous automatic recycling tyre oil plant final products:

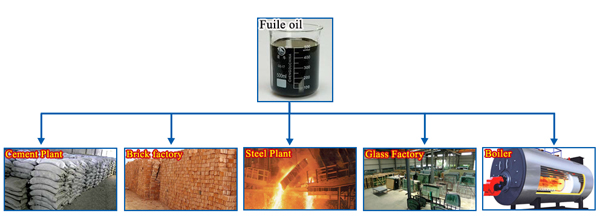

Fuel oil (45% to 52%)

The main product produced by continuous automatic recycling tyre oil plant is the fuel oil that is wide used for industrial and commercial purposes.

Fuel oil applications

Fuel oil applications

Carbon black (30% to 35%)

Carbon black can be used as raw material or main ingredient in many industries and the chemical structure of carbon black strengthens, lengthens the endurance, and improves the coloring features of the materials. Carbon black produced by Pyrolysis process (CBp) is more economical compared to carbon black produced primarily from petroleum and is more price-efficient to be used as an ingredient in the industries listed.

Carbon black applications

Carbon black applications

Steel wire (10% to 15%)

Steel wires can be sold to steel factory or scrap dealers.

Non-Condensable gas (10% to 12%)

Non-Condensable gas arised during the pyrolysis process can be utilized as a source of energy to heat the pyrolysis reactor.

contact us

CONTACT US