WhatsApp

WhatsApp

♥ Why we developed the rubber powder production line?

With the rapid development of the world automobile industry and transportation industry, the demand of all kinds of tires are increasing day by day.

At present, more than billions of tires are sold all over the world every year. According to the research, 50-55% raw rubber are used for the tire manufacturing every year. For security, automobiles should change tires after every 30,000-50,000 km trip distance. In this way, billions of waste tires, about 17 millions tons can be produced in one year. And waste tires is a kind of non-fusible or refractory polymer elastomer materisl, which will take hundreds of years to decompose. With the time goes, the waste tire problem has become serious to environment. How to dispose the waste tires also become more and more important in every countries.

Because of this, except the tire pyrolysis machine, the rubber powder production line is another new develop and design equipment used for recycling waste tires to rubber pwder for recycle use.

♥ What's rubber powder production line?

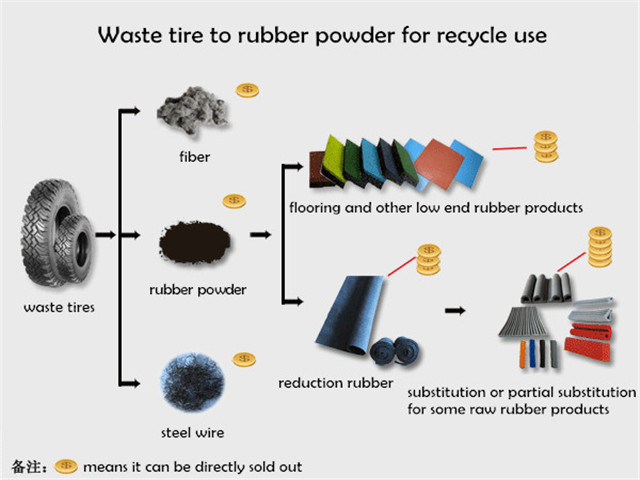

Rubber powder production line is used for processing used tires and rubbers to fine rubber powders. Not only this, the rubber powder equipment can

separate the three major raw materials contained in tires: rubber, steel wire and fiber once for all. Then through the rubber reducer can restore the

used tires and rubbers to the conditon before vulcanization, which can be used for making all kids of rubber products, so as to achieve the waste recycling.

♥ What kind of rubber pwder production line we can provide?

To better meet customers' demand, we supply two kinds of rubber powder production line. One is semi-automatical rubber powder production line. And the other one is fully-automatical rubber powder production line.

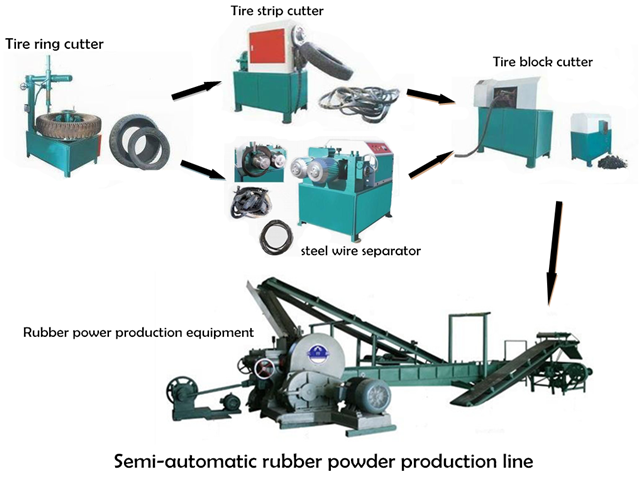

♦ Semi-automatica rubber powder production line:

Semi automatical rubber powder production line mainly consist of five parts: tire ring cutter, tire strip cutter, steel wire separator, tire block cutter and rubber powder production equipment.

(1) Tire ring cutter is used for cutting the tire steel wire circle (two tire sidewalls) from tire body for further processing;

(2) Tire strip cutter is used for cutting the tire body to tire strips for tire block cutter;

(3) Tire steel wire separator is used for separating the steel wire from the tire sidewalls;

(4) tire block cutter is used for cutting the tire strips to tire blocks ( 3 - 5cm sizes);

(5) Rubber powder production equipment is the last step to process the tire blocks to rubber powder.

And we have different standards of rubber powder processing equipments can process the rubber powder into different sizes (meshes) for different uses.

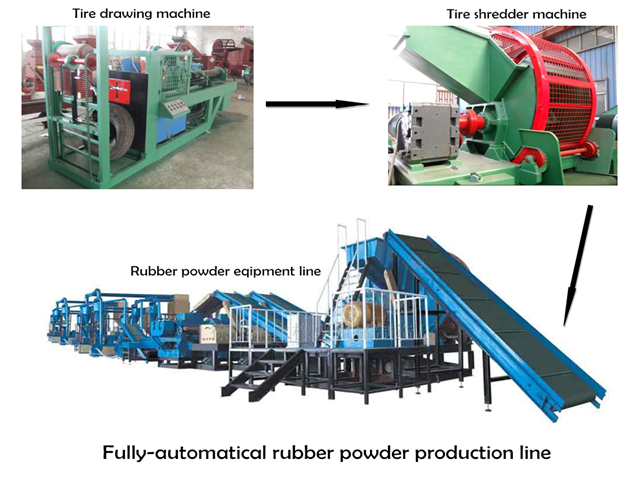

♦ Fully-automatical rubber powder production line:

Fully automatical rubber powder production line mainly consist of only three parts: Steel wire drawing machine, Tire shredder and rubber powder production equipment.

(1) Steel wire drawing machine, which is used for pulling out the steel wire from tires automatically.

(2) Tire shredder is another kind of tire cutting machine, but the biggest advantage of it is it can directly process the whole tires or big tire blocks into small pieces (usually 3 - 5cm sizes) for rubber powder processing line;

(3) Rubber powder production equipment is the last step to process the tire blocks to rubber powder.

And we have different standards of rubber powder processing equipments can process the rubber powder into different sizes (meshes) for different uses.

contact us

CONTACT US