WhatsApp

WhatsApp

3.Tight construction, small space and simple technique flow.

4. Low energy-consuming and good performance-cost ratio

5.Hight automatization, fewer labors requirement.

6.Reasonable construction,easy operation and low rate of breakdown

7.Environmental-protection,no pollution(no waste gas,no waste residue,no polluted water),meeting the environmental requirement of the government.

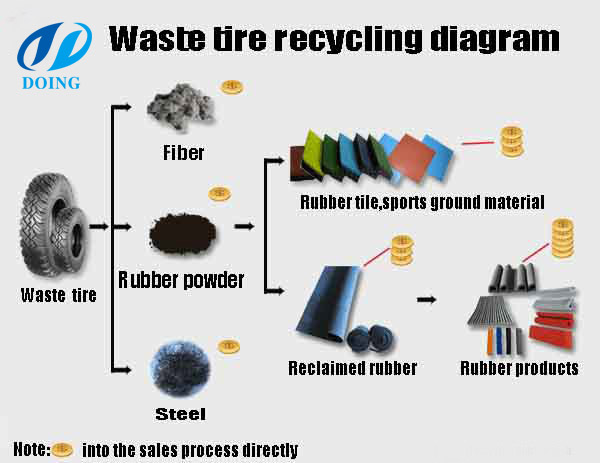

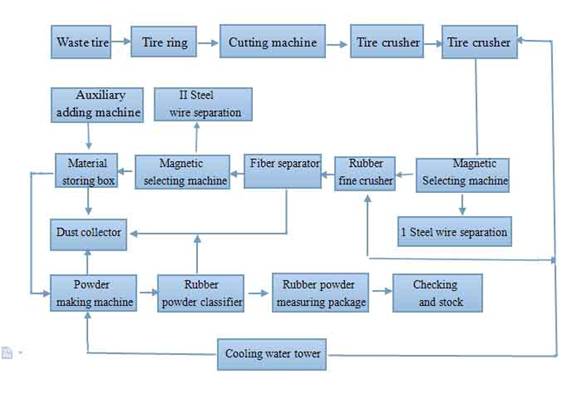

flow chart of waste tire recycling rubber powder machine

Function:Our whole waste tires recycling rubber powder machine is used to make waste tires and rubber powder.

| Mode |

Tire bead cutting machine |

Thread rolling machine |

Tire Crusher |

| Picture |

|

|

|

|

Function |

Separate the sidewall and top of the tire, prolong the life span of the next machine’s cutter, and convenient the succeeding work |

Use physical method to peel the heavy steel wire from the tire side wall under normal temperature, remain integrity of the steel. |

Scarp the whole tire without tire bead to rubber strips or rubber blocks. |

| Mode |

ZQTQ—F1200 |

ZCTC-F-ZY |

ZQTP—Z(50×50) |

| Size |

1480mm×1460 mm×1200 mm |

1330mm×1080 mm×1330 mm |

1200—2500KG/H |

| Capacity |

1200-1600KG/H |

40—60 tire/H |

|

| Weight |

1.8T |

1200kg-1600kg |

2.5T |

| Power |

2.2KW |

11KW |

15KW |

waste tire recycling rubber powder machine

flow diagram of waste tire recycling rubber powder machine

contact us

CONTACT US