WhatsApp

WhatsApp

A large number of people intend to build a waste tyre oil plant in India, because it not only does not pollute the environment, but also can recycle waste tyres to get new energy and obtain benefits. And many people are curious about how much it costs to invest in a tire oil plant in India. Here I will take DOING waste tire pyrolysis machine as an example to give you more information about the cost of tyre oil plants in India.

The tyre oil plant cost in India is about from US$20,000 to US$600,000, because it depends on many factors, such as the price of waste tyre pyrolysis machine, the size of plant area, the price of raw material, and water electricity and labor costs, etc.

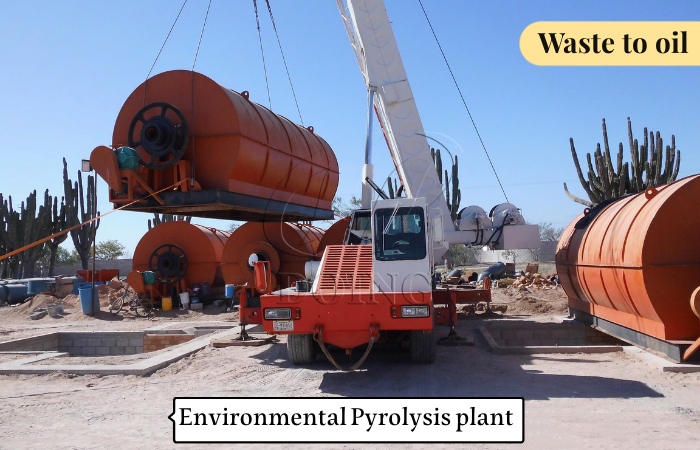

The installation site of DOING wsate tyre pyrolysis machine

The installation site of DOING wsate tyre pyrolysis machine

When choosing DOING waste tyre pyrolysis machine, the input cost varies with the processing capacity, machine type and configuration of equipment.

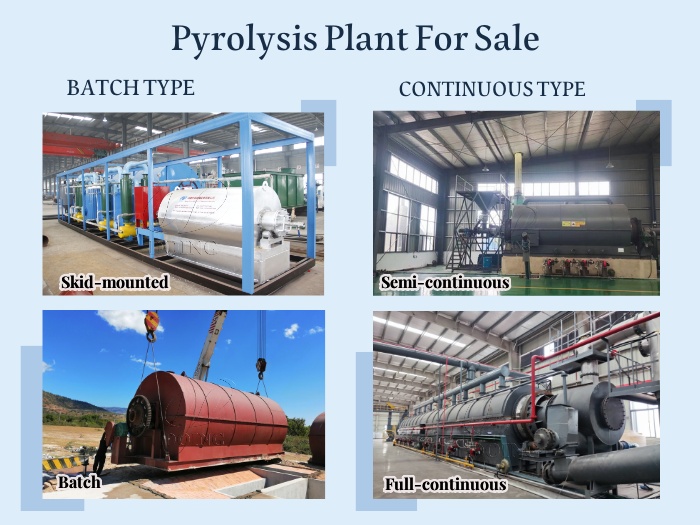

DOING has small skid-mounted waste tyre pyrolysis machines(100/500kg) and pyrolysis machines with a relatively larger processing capacity (1 ton-50+ton). And we have different pyrolysis machine types for you to choose, such as batch, semi-continuous, and fully continuous type waste tyre pyrolysis machines. The higher the processing capacity, the higher the automation degree, the higher the waste tyre pyrolysis machine cost.

Here we listed the investment cost of waste tyre pyrolysis machine for your reference, and it is between US$18000 and US$500,000. About the detailed and latest quotations, welcome to contact us.

The different types of DOING pyrolysis machine

The different types of DOING pyrolysis machine

The selected configuration of waste tyre pyrolysis machine is different, and the cost is different. And the optional devices can be purchased and configured according to personal budget and needs.

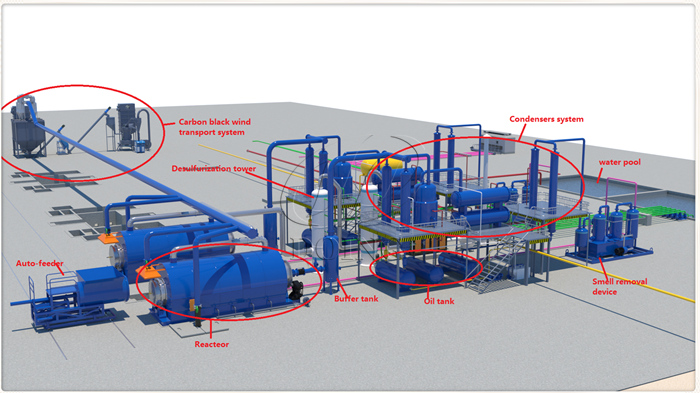

The optional configuration devices of DOING include automatic feeder, wire drawing machine, deodorization system, desulfurization tower, vacuum negative pressure device, carbon black elevator, carbon black transport system, burner and so on.

DOING tire pyrolysis production line

DOING tire pyrolysis production line

For example, the vacuum negative pressure device can avoid flash explosion and improve the oil yield; the deodorization system consists of a buffer tank, spray tower and water seal, to remove irritating hydrogen sulfide gases.

The tyre oil plant area mainly depends on the size of waste tyre pyrolysis machine, and you could also take the raw material storage area and final products storage sear into consideration. Taking the DOING 10TPD waste tyre oil plant as an example, the whole installation area is about 35mx15m. According to this area and the local rented land price in India, the investment cost of tire to oil pyrolysis plant area can be calculated.

In India, waste tires are rich in resources, so the cost of raw material input will not cost a lot. However, the waste tire market may fluctuate slightly, you can pay more attention to the market of waste tires in the early stage, and then choose a suitable price to buy.

Waste tyres in India

Waste tyres in India

DOING tyre oil pyrolysis plant uses circulating water, so the cost of water will not be very high. Different processing capacity require different power, and different types of pyrolysis plant require different labor numbers. For details of power and labor required for specific models, please consult us online.

The project cases of DOING pyrolysis machine

The project cases of DOING pyrolysis machine

The above is a simple analysis of setting up tyre oil plant cost in India. Doing company is a professional manufacturer of waste tyre oil pyrolysis machines, which has many project cases in India, with rich experience, we can escort you to establish a tire oil plant locally smoothly. (Recommended reading: Waste pyrolysis and distillation plant projects installed by DOING in India) If you want to join this industry, don't hesitate to choose DOING company.

contact us

CONTACT US