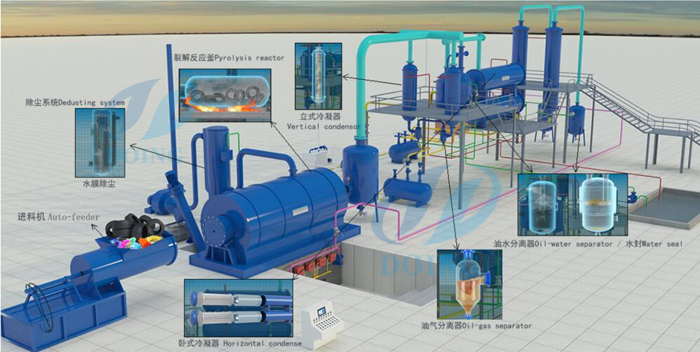

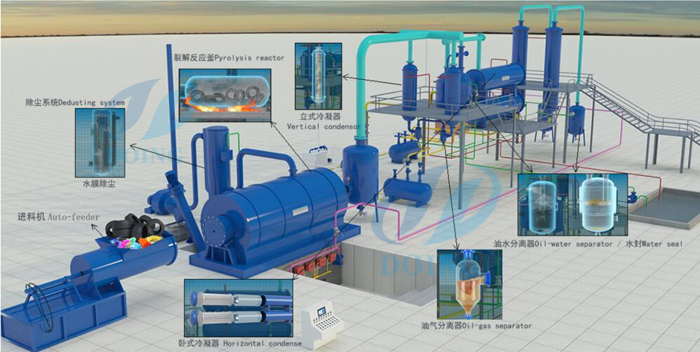

Converting waste plastic to oil machine

Converting waste plastic to oil machine is a new technology. By the technology, we can convert the plastic to oil ,carbon black, which is seen as wast eplasitc to oil. With years researching and developing,we have manufactured the latest generation convert plastic to oil machine.According to the feedback of customers, we consistently improve the quality of this machine. Finally, we manufactured the latest generation convert waste plastic to oil machine.

Convert wasteplastic to oil machine

Converting waste plastic to oil machine advantage

1. Safe. The convert plastic to oil machine is equipped with mature safety devices, such as alarm for over temperature and pressure, auto pressure releasing system, extra gas recycling system and fire fighting device, which will guarantee 100% safety in the pyrolysis process.

2. Energy-saving. By the extra gas recycling system, the gas that can not be condensed will be recycled to the burning room. It can replace the fuel material to heat the reactor, which will reduce additional fuel consumption.

3. Environment friendly. In the dedusting system, three steps (water spray, ceramic ring filter, washing chamber) are used to dedust the extra gas and more than 95% of the dust would be removed. The released gas is pollution-free and can be discharged into the air directly.

Compared with the old plastic to oil machine,there have some advantages with the latest generation machine:

Convert plastic to oil machine working process

1. The latest generation convert plastic to oil machine adopt the newest technology toreduce the pollution to the environment, it produce nearly no pollution to theenvironment. It absolutely meets the stand of the environmental protection. And meet the command of the notion of sustainable development.

2. The latest generation convert plastic to oil machine is more effective. With fewer raw materials it can produce crude oil as many as it can. And the time is shorter compared with old machine. What is worse, 2 workers are enough tooperation the machine.

3. The traditional way to convert plastic to oil machineis to heat the plastic when the temperature reached its boiling point,let it vaporize and then condense the vapor. Finallywe will get liquid oil. The latest generation convert plastic to oil machine adopts chemical process which breaks long chains into shorter ones.This allows a refinery to turn diesel fuel into gasoline depending on the demand for gasoline. So we can get higher quality oil.

4. The latest generation convert plastic to oil machine is the cheapest during the history of my company. And it is cost-effective.it can maximize save the prime cost, and create more economics profits.

Convert waste plastic to oil machine technical parameter:

|

Technical parameter of convert waste plastic to oil machine |

|

No. |

Items |

Contents |

|

1 |

Equipment type |

DY-1-6 |

DY-1-8 |

DY-1-10 |

|

2 |

Raw material |

Waste plastic |

Waste plastic |

Waste plastic |

|

3 |

Structural form |

Horizontal rotation |

Horizontal rotation |

Horizontal rotation |

|

4 |

24-hour Capacity |

6 ton |

8 ton |

10 ton |

|

5 |

Oil yield |

2.7-3.3ton |

3.6 -4.4ton |

4.5 -5.5ton |

|

6 |

Operating pressure |

Normal |

Normal |

Normal |

|

7 |

Material of pyrolysis Reactor |

Q245R |

Q245R |

Q245R |

|

8 |

Thickness of pyrolysis Reactor |

16mm |

16mm |

16mm |

|

9 |

Rotate speed of pyrolysis Reactor |

0.4turn/minute |

0.4turn/minute |

0.4turn/minute |

|

10 |

Total power |

19KW |

19KW |

19KW |

|

11 |

Mode of cooling |

Water cooling |

Water cooling |

Water cooling |

|

12 |

Cooling area of condenser |

100sqm |

100sqm |

100sqm |

|

13 |

Kind of transmission |

Internal gear drive |

Internal gear drive |

Internal gear drive |

|

14 |

Noise dB(A) |

≤85 |

≤85 |

≤85 |

|

15 |

Size of Reactor(D×L) |

2200×6000 |

2200×6600 |

2600×6600 |

|

16 |

Working form |

Intermittent operation |

Intermittent operation |

Intermittent operation |

|

17 |

Delivery time |

20days |

20days |

20days |

|

18 |

Weight |

27T |

30T |

35T |

|

Prepared by customer about convert waste plastic to oil machine |

|

No. |

Item |

Consumption |

|

1 |

Coal(for choice) |

500kg/day |

|

2 |

Wood(for choice) |

800kg/day |

|

3 |

Natural gas(for choice) |

100-150kg/day |

|

4 |

Oil(for choice) |

300-350kg/day |

|

5 |

Electricity |

244kwh/day |

|

6 |

Water(recycled) |

60㎥ /month |

|

7 |

Total power |

19kw |

|

8 |

Land area |

35m*15m |

Convert waste plastic to oil machine can disposal tires and rubber to fuel oil. Usually plastic oil yield is about 20%-95% (according to plastic type).

Fuel oil from convert plastic to oil can be using as heating material into cement factory, glass making factory, steel factory, brick factory boiler etc.

Fuel oil usage

Carbon black from convert plastic to oil machine can be application to :electric cable jacketing,rubber additive,heat isolation,black colorant in rubber materials

Carbon black usage

We put out heart and soul into servingour customers. It is a wisdom choice to have a corporation with us. We are Henan DOING Mechanical Equipment Co,Ltd. Welcome your visit!

WhatsApp

WhatsApp