Waste rubber

Waste rubber

You have used and waste rubber tires. Tire disposal should be simple, convenient and fit with your business’ goals. Your waste waste rubber tires are virtually 100% recyclable at Doing group– so they’re not waste at all!

In the modern days, waste rubbers tire are serious issues for many countries. More wastes mean more pollution. In the times that almost all people are seeking for the “Green” life style, machines to dispose various kinds of wastes are certainly warmly welcomed.

Waste rubber tire recycling pyrolysis plant

Doing group, the professional waste rubber tire recycling pyrolysis plant manufacturer in China, supplies several types ofused rubber process oil machfacturers plant ,waste rubber scrap recycling pyrolysis plant which adopts the most advanced technologies and raw materials with excellent quality.The waste rubber tire pyrolysis plant can convert waste rubber tire to fuel oil ,carbon black and gas.

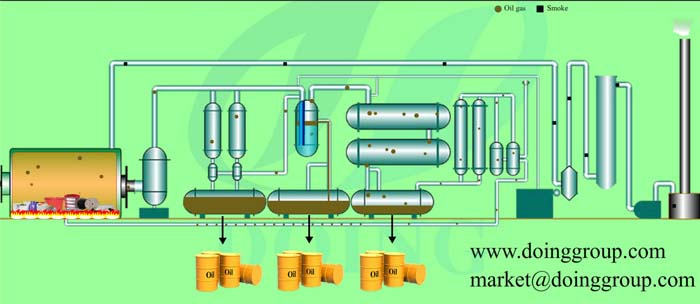

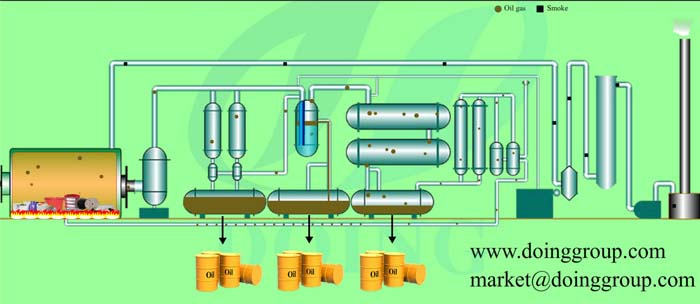

Waste rubber tire recycling pyrolysis plant working process

Waste rubber tire recycling pyrolysis plant wortking process

Feed waste rubber tire into the reactor with auto-feeder, seal the reactor gate and begin to heat the reactor by burning fuel materials in the combustion system, the fuel material can be coal, wood, natural gas and fuel oil. There is a thermocouple installed at the oil gas outlet valve to test the temperature of the oil gas, when thermocouple shows a certain temperature, the oil gas will come out and flow into the cooling system and be converted into liquid oil. At the same time, the oil gas conations CH4, C2H6, C3H8, C4H10 and H2 which cannot be cooled under normal pressure will be recycled back to combustion system to burn as fuel material. The dust and sulfur gas will be removed by the dust removing system. After the gas oil run out, there are slags (carbon black) inside of the reactor,.

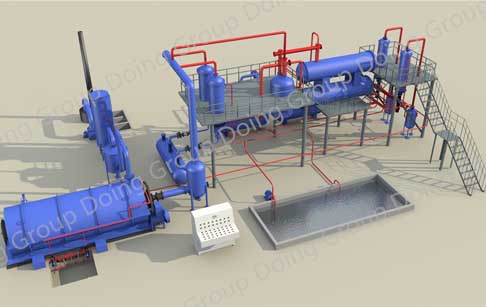

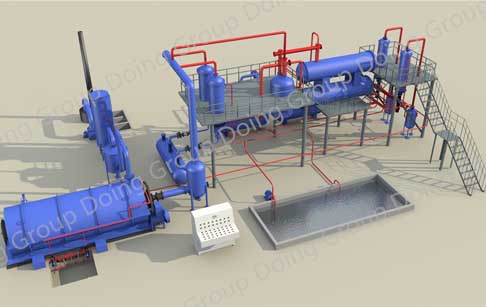

3d picture of waste rubber tire recycling pyrolysis plant

As rubber tire recycling pyrolysis plant manufacturer-DOING will provide customer a good quality machine with adopt fully automatic vacuum carbon black discharging system that extend the service time.

Choosing the suitable raw material is important for customers, it concerns the real profit you can get from your material. Not all kinds of waste rubber can get oil, if you want to get crude fuel oil with high oil yield from waste rubber, please refer to the following form: Here I need to stress that the oil rate only for your reference, as different rubber different result, such as some rubber has very dirty slag, and the rubber is very wet.

General Rubbers:

Big truck tires: 45%

Small car tire and bike tire: about 35%

Rubber electric cable and shoe sole: about 35%

Mixture shoe sole: about 30%

Sport shoes: 20%-30%

Waste chemical fiber carpet: more than 30%

Technical data of waste rubber tire recycling pyrolysis plant

|

Technical parameter of waste rubber tire recycling pyrolysis plant |

|

No. |

Items |

Contents |

|

1 |

Equipment type |

DY-1-6 |

DY-1-8 |

DY-1-10 |

|

2 |

Raw material |

Waste rubber/tire |

Waste rubber/tire |

Waste rubber/tire |

|

3 |

Structural form |

Horizontal rotation |

Horizontal rotation |

Horizontal rotation |

|

4 |

24-hour Capacity |

6 ton |

8 ton |

10 ton |

|

5 |

Oil yield |

2.7-3.3ton |

3.6 -4.4ton |

4.5 -5.5ton |

|

6 |

Operating pressure |

Normal |

Normal |

Normal |

|

7 |

Material of pyrolysis Reactor |

Q245R |

Q245R |

Q245R |

|

8 |

Thickness of pyrolysis Reactor |

16mm |

16mm |

16mm |

|

9 |

Rotate speed of pyrolysis Reactor |

0.4turn/minute |

0.4turn/minute |

0.4turn/minute |

|

10 |

Total power |

19KW |

19KW |

19KW |

|

11 |

Mode of cooling |

Water cooling |

Water cooling |

Water cooling |

|

12 |

Cooling area of condenser |

100sqm |

100sqm |

100sqm |

|

13 |

Kind of transmission |

Internal gear drive |

Internal gear drive |

Internal gear drive |

|

14 |

Noise dB(A) |

≤85 |

≤85 |

≤85 |

|

15 |

Size of Reactor(D×L) |

2200×6000 |

2200×6600 |

2600×6600 |

|

16 |

Working form |

Intermittent operation |

Intermittent operation |

Intermittent operation |

|

17 |

Delivery time |

20days |

20days |

20days |

|

18 |

Weight |

27T |

30T |

35T |

|

Prepared by customer about waste rubber tire recycling pyrolysis plant |

|

No. |

Item |

Consumption |

|

1 |

Coal(for choice) |

500kg/day |

|

2 |

Wood(for choice) |

800kg/day |

|

3 |

Natural gas(for choice) |

100-150kg/day |

|

4 |

Oil(for choice) |

300-350kg/day |

|

5 |

Electricity |

244kwh/day |

|

6 |

Water(recycled) |

60㎥ /month |

|

7 |

Total power |

19kw |

|

8 |

Land area |

35m*15m |

Waste rubber tire recycling pyrolysis plant final product application

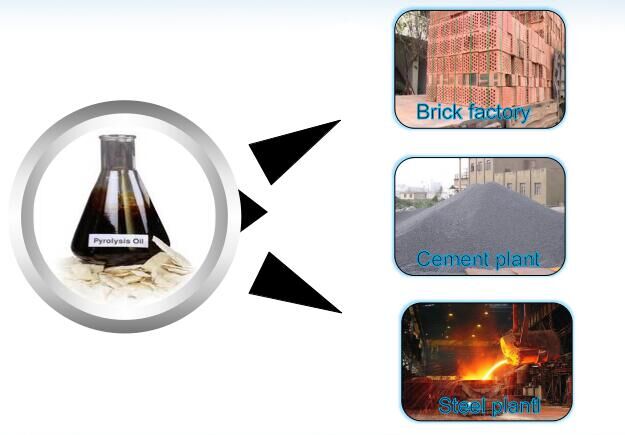

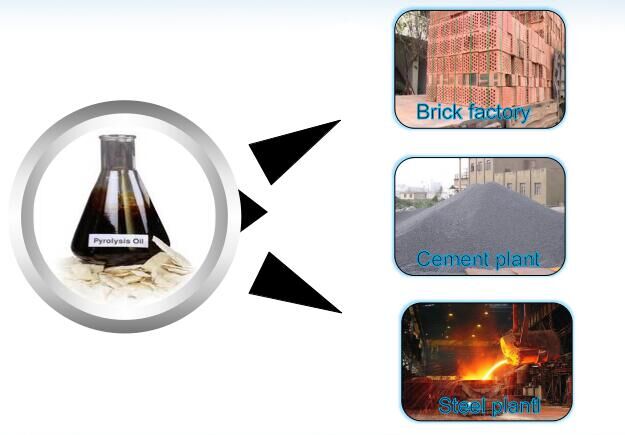

FUEL OIL (40% to 45%)

Fuel oil application

Fuel oil application

The main oil product produced by our recycling application is the fuel oil that is wide used for industrial and commercial purposes. The oil has 40% to 45% of the amount of recycled scrap tyres, which will be carried with licensed tanker trucks.

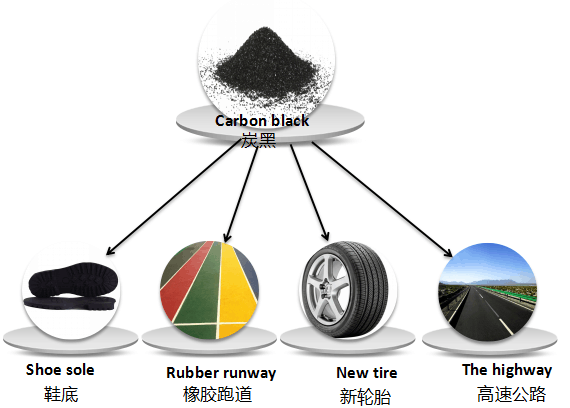

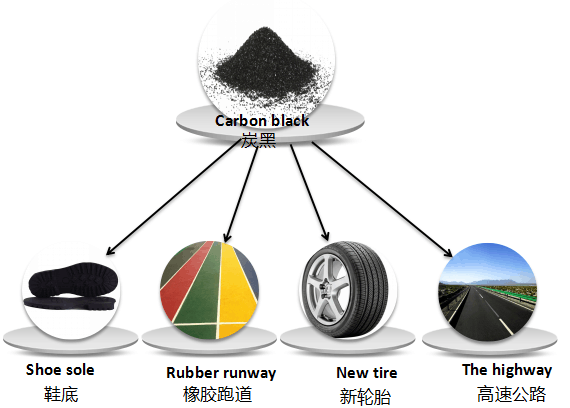

CARBON BLACK (30% to 35%)

Carbon black application

Carbon black application

Carbon Black is the main product recycled by Pyrolysis technology. The amount of recycled carbon black is 30% to 35% (depending on the type of tyres) of the total amount of scrap tyres recycled in the system. Carbon black is used as raw material or main ingredient in many industries and the chemical structure of carbon black strengthens, lengthens the endurance, and improves the coloring features of the materials.

Carbon black produced by Pyrolysis process (CBp) is more economical compared to carbon black produced primarily from petroleum and is more price-efficient to be used as an ingredient in the industries listed;

* Electric cable jacketing

* Conveyor band

* Carrier Bands

* Hose and doormat

* Black nylon bag

* Rubber additive

* Automotive spare parts

* Heat isolation

* Black colorant in rubber materials

* Plastic pipes

* Industrial rubber products

* Fire fighting

GAS (10% to 12%)

Non-Condensable gases arise during the pyrolysis process.

Some advantages such as…..

* It has higher calorific value as compared to Natural Gas.

* It can be replaced where Natural Gas and Propane are stored.

* The high energy gas may be utilized as a source of energy for the Pyrolysis process.

* The amount of gas generated in the system is 12% to 15% of the total amount of recycled tyres and considering the 10 ton scrap tyre/day recycling capacity, the facility generates 1200-1500 m3/day gas, which has an enormous energy potential when evaluated.

WhatsApp

WhatsApp