WhatsApp

WhatsApp

Doing waste plastic to fuel oil pyrolysis plant can convert waste plastic to fuel oil, carbon black with lower cost and higher fuel oil output.

Doing waste plastic to fuel oil pyrolysis plant

Doing waste plastic to fuel oil pyrolysis plant

What is pyrolysis?

Pyro = heat; lysis = break down. Pyrolysis is chemical reaction. This reaction involves molecular breakdown of larger molecules into smaller molecules in presence of heat. Pyrolysis is also known as thermal cracking, cracking, thermolysis, depolymerization, etc.

Plastic pyrolysis involves subjecting plastic to high temperature of 400 to 450 degree Celsius, in absence of oxygen. In case of oxygen is present plastic will start burning. During pyrolysis plastic breaks down into smaller molecules of pyrolysis oil, pyrolysis gas and carbon black. Pyrolysis is great a way of recycling waste plastics. This waste plastic to fuel oil pyrolysis plant can also used for waste tire recycling.

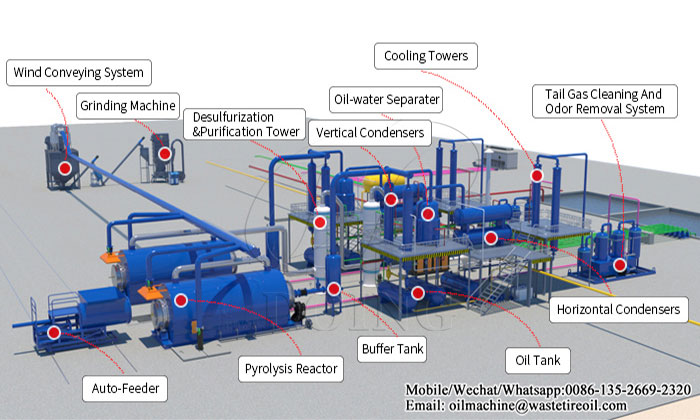

The composition of waste plastic to fuel oil pyrolysis plant:

Doing waste plastic to fuel oil pyrolysis plant is mainly composed of feeding system, horizontal pyrolysis reactor, condensing system, oil tank, combustible gas recovery system, discharging system, tail gas purification system, flue gas purification system, pressure and temperature multi-point monitoring system, etc.

The composition of waste plastic to fuel oil pyrolysis plant

The composition of waste plastic to fuel oil pyrolysis plant

Waste plastic to fuel oil pyrolysis plant advantages:

1. Complete plastic feed, no need to break, which reduces cost.

2. Discharge process through pulse dust removal processing, no dust emissions.

3. Adopt multilevel cooling circulation to get more fuel oil.

4. Easy operation, high efficiency and 2-3 people to operate.

5. Waste plastic to fuel oil pyrolysis plant adopts fully automatic submerged arc welding process, through x-ray detection, to improve the security of plant.

| Technical parameter of Waste plastic to fuel oil pyrolysis plant | ||||

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | Waste plastic | Waste plastic | Waste plastic |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

| Final products | Images | Applications |

| Fuel Oil |

|

It can be widely used as fuel in industrial plants, such as glass plants, cement plants, power plants, etc. For more valuable and widely used fuel oil, it can also be further refined into diesel by our tyre oil to diesel distillation plant. |

| Carbon Black |

|

It can be sold directly or used as a raw material or major component in many industries, such as making pigments, shoe soles, tyres, etc. |

| Steel wire |

|

It can be sold directly or reprocessed. |

| Combustible gas |

|

It can be recycled to furnace to heat reactor instead of coal/wood/oil/natural gas. |

contact us

CONTACT US