Waste plastic

Economic growth and changing consumption and pr oduction patterns are resulting into rapid increase in generation of waste plastics in the worl d. In Asia and the Pacific, as well as many other developing regions, plastic consumption has increas ed much more than the world average due to rapid urbanization and economic development. The world's annual consumption of plastic mate rials has increased from around 5 million tonnes in the 1950s to nearly 100 million tonnes; thus, 20 tim es more plastic is produced today than 50 years ago. This implies that on the one hand, more resources are being us ed to meet the increased demand of plastic, and on the other hand, more plastic waste is being generated. Due to the increase in generation, waste plastics are becoming a major stream in solid waste. After food waste and paper waste, plastic waste is the major constitute of municipal and industrial waste in cities. Even the cities with low economic growth have st arted producing more plastic waste due to plastic packaging, plastic shopping bags, PET bottles and other goods/appliances using plastic as the major component. This increase has turned into a major challenge for local authorities, responsible for solid waste management and sanitation. Due to lack of integrat ed solid waste management, most of the plastic waste is neither collected properl y nor disposed of in appropria te manner to avoid its negative impacts on environment and public h ealth and waste plastics are caus ing littering and chocking of sewerage system. On the other hand, waste plastic pyrolysis plant can provide an opportuni ty to collect and dispose of plastic waste in the most environm ental friendly way and it can be conve rted into a resource.

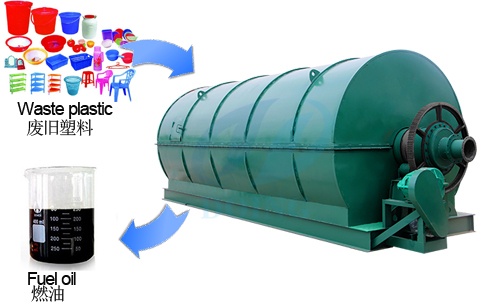

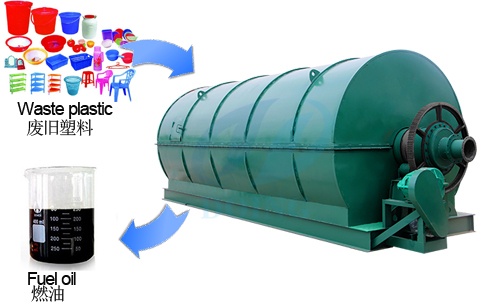

Waste plastic pyrolysis plant

Plastic Pyrolysis Plant converts waste plastics into high grade diesel fuel. The systems use a continuous liquefaction technology alongside a unique catalytic breakdown process that turns waste materials into gases and liquids. The end products can be used brick factory,cement factory,glass factory ,etc,

Plastic Pyrolysis Plants fuel technologies are based on new approaches to chemical processing that are generally referred to as chemical process intensification. Chemical process intensification involves accelerating the rate of a chemical process in order to reduce processing time while also reducing energy and material requirements and increasing product quality.

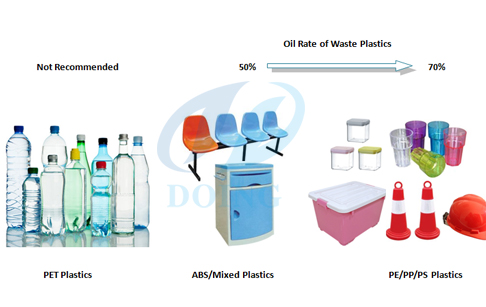

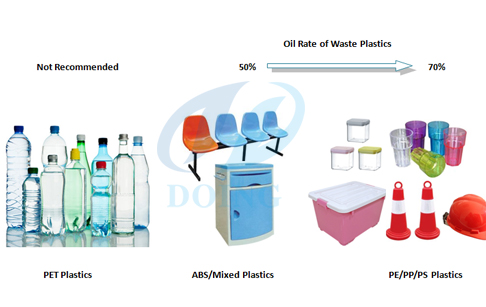

Approx oil yield rate of different raw material

PE/ldpe/hdpe 50%-75%

PP 50%-75%

PS 50%-75%

ABS 40%

Leftovers of paper Wet 15-20%, dry 60%

House garbage 35-50%

Plastic cable 80%

Plastic bag 50%

Submarine cable 75%

Rubber cable 35%

Sole 35%

PVC Not suitable

PET Not suitable

Waste plastic pyrolysis plant technical data

|

Technical parameter of Waste plastic pyrolysis plant |

|

No. |

Items |

Contents |

|

1 |

Equipment type |

DY-1-6 |

DY-1-8 |

DY-1-10 |

|

2 |

Raw material |

Waste plastic |

Waste plastic |

Waste plastic |

|

3 |

Structural form |

Horizontal rotation |

Horizontal rotation |

Horizontal rotation |

|

4 |

24-hour Capacity |

6 ton |

8 ton |

10 ton |

|

5 |

Oil yield |

2.7-3.3ton |

3.6 -4.4ton |

4.5 -5.5ton |

|

6 |

Operating pressure |

Normal |

Normal |

Normal |

|

7 |

Material of pyrolysis Reactor |

Q245R |

Q245R |

Q245R |

|

8 |

Thickness of pyrolysis Reactor |

16mm |

16mm |

16mm |

|

9 |

Rotate speed of pyrolysis Reactor |

0.4turn/minute |

0.4turn/minute |

0.4turn/minute |

|

10 |

Total power |

19KW |

19KW |

19KW |

|

11 |

Mode of cooling |

Water cooling |

Water cooling |

Water cooling |

|

12 |

Cooling area of condenser |

100sqm |

100sqm |

100sqm |

|

13 |

Kind of transmission |

Internal gear drive |

Internal gear drive |

Internal gear drive |

|

14 |

Noise dB(A) |

≤85 |

≤85 |

≤85 |

|

15 |

Size of Reactor(D×L) |

2200×6000 |

2200×6600 |

2600×6600 |

|

16 |

Working form |

Intermittent operation |

Intermittent operation |

Intermittent operation |

|

17 |

Delivery time |

20days |

20days |

20days |

|

18 |

Weight |

27T |

30T |

35T |

|

Prepared by customer about Waste plastic pyrolysis plant |

|

No. |

Item |

Consumption |

|

1 |

Coal(for choice) |

500kg/day |

|

2 |

Wood(for choice) |

800kg/day |

|

3 |

Natural gas(for choice) |

100-150kg/day |

|

4 |

Oil(for choice) |

300-350kg/day |

|

5 |

Electricity |

244kwh/day |

|

6 |

Water(recycled) |

60㎥ /month |

|

7 |

Total power |

19kw |

|

8 |

Land area |

35m*15m |

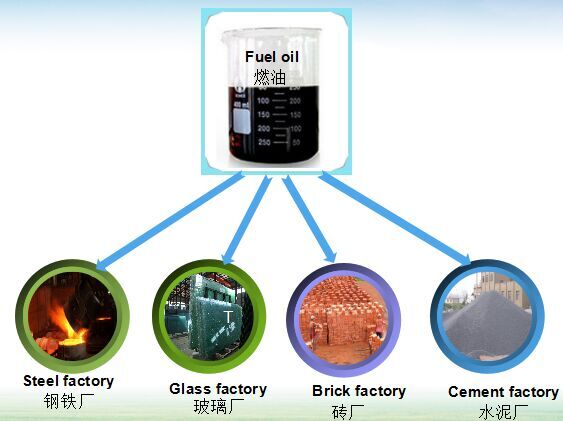

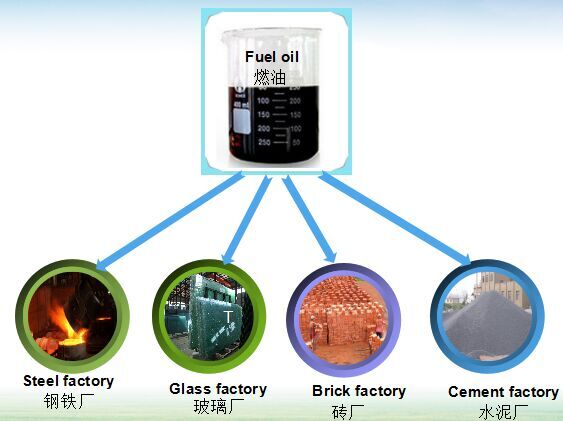

Fuel oil from waste plastic pyrolysis plant used in below industries

Fuel oil application

A.power plant factory

B.glass factory

C.cement factory

D.ceramic fatory

E.aluminum factory

F.boiler factory

G.central heating factory

H.painting factory

Carbon black application

Carbon black from waste plastic pyrolysis plant

A.electric cable jacketing

B.conveyor ban

C.hose and doormat

D.black nylon bag

E.rubber additive

F.automatic spare parts

G.heat isolation

H.black colorant in rubber materials

WhatsApp

WhatsApp