Fully continuous tyre pyrolysis plant

Doing company began to manufacture waste tyre pyrolysis plant since 1993. We mastered mature pyrolysis technology on manufacturing batch type pyrolysis plant for 20 years. Our pyrolysis plant have been exported and installed in many foreign countries like Italy, Romania, Macedonia, Albania, Estonia, Rusia, Egypt, Ethopia, Nigeria, Congo, Lebanon, Jordan, Iran, Pakistan, Kazakhstan, India, Tailand, Malaysia, Mexico, Panama, Guatemala, Aruba, Jamaica, Ecuador, Haiti etc.

Pyrolysis plant installed in different countries

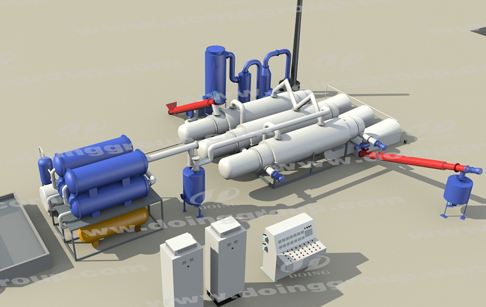

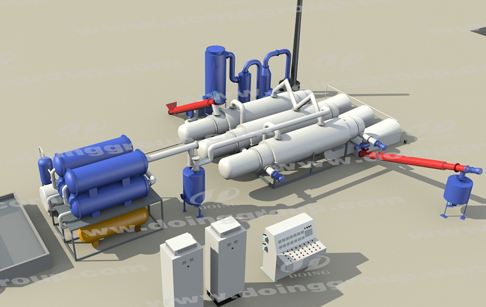

3D draw of Fully continuous tyre pyrolysis plant

With more than ten years of experience and efforts,Doing produced fully continuous tyre pyrolysis plant .

The fully continuous tyre pyrolysis plant is equipped with automatic feeding and discharging system, which can realize feeding materials on one side and discharging the slag continuously from the other side. It not only can dispose 30-50 tons waste tyres per day but also can work continuously for 24 hours without a stop.

The raw material of fully continuous tyre pyrolysis plant

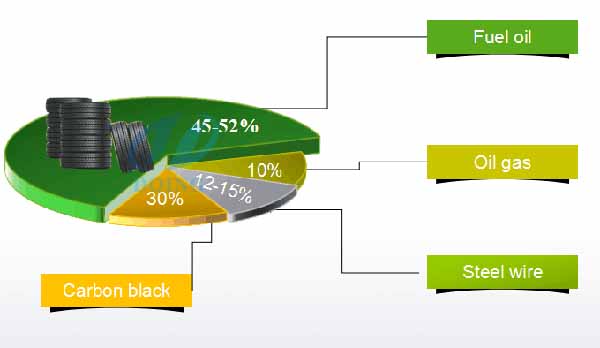

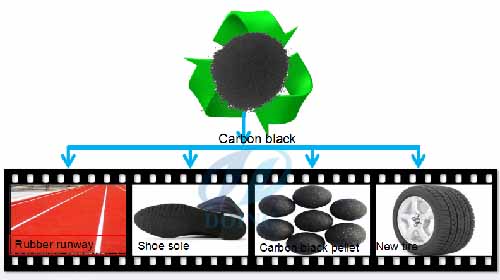

The objective of fully continuous waste tyre pyrolysis plant is continuous pyrolysis process. It can produce not less 45%-52% waste oil, 30%-35% carbon black and 12%-15% steel wire. The work process of Fully continuous tyre pyrolysis plant is similar as batch waste tyre pyrolysis plant. However, the whole working process of fully continuous waste tyre pyrolysis plant is much more efficient, and the cost of working fully continuous waste tyre pyrolysis plant is much lower.

Fully continuous tyre pyrolysis plant raw material

Fully continuous tyre pyrolysis plant raw material

1.Waste tire/tyre

2.Waste plastic

3.Waste rubber

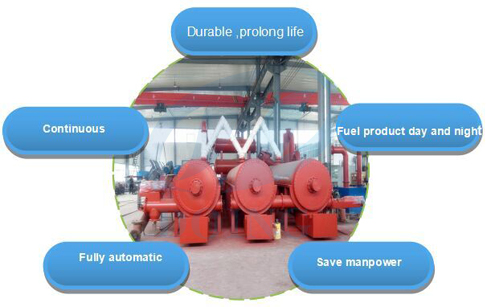

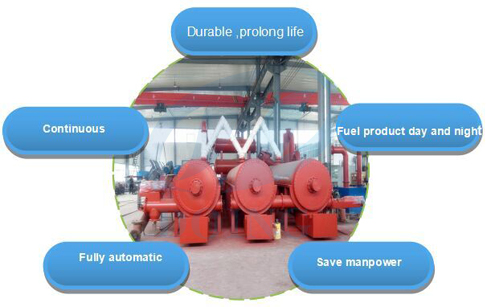

Fully continuous tyre pyrolysis plant advantage

Fully continuous tyre pyrolysis plant advantage

1. The Fully continuous tyre pyrolysis plant adopts the screw feeding sealing system technology, which is hold by the company’s invention patents, hot air heating furnace circulating heating technology, heat drying technology with high heat exchange efficiency and capacity. Impeccable electrical control system save labor costs. Three waste utilization reasonable recovery can basically realize zero emissions, which is safe and environmental protecting.

2. The Fully continuous tyre pyrolysis plant produces some gas, which is enough to meet the needs of device self-heating, so the additional fuel consumption is less, and this plant can use own end products of oil as a recycled energy heating for the whole process.

3. Due to its high automation degree, it has a strict demand of the raw material. The tire and rubber should be broken into 30-50mm rubber pieces by the crusher to meet the requirement of the spiral feeding device. As plastic, PET can’t be the raw material for pyrolysis. And the sludge oil should be pre-heated to remove the water. But the working efficiency is increased a lot.

4. The Fully continuous tyre pyrolysis plant can save the labor cost and energy cost, which makes it more profitable than the batch and semi-continuous plant.

Fully continuous waste tyre pyrolysis plant technical data

|

No. |

Item |

Specifications |

|

1 |

Model |

DY-C-10 |

DY-C-20 |

DY-C-30 |

DY-C-50 |

DY-C-60 |

DY-C-80 |

DY-C-100 |

|

2 |

Cpacity |

10T/D |

20T/D |

30T/D |

50T/D |

60T/D |

80T/D |

100T/D |

|

3 |

Power |

35Kw |

50Kw |

65Kw |

80Kw |

90Kw |

105Kw |

120Kw |

|

4 |

Working type |

Continuous |

|

5 |

Reactor deisgn |

Mutiple reactors (The quantity and size depends on the raw material condition) |

|

6 |

Rotating |

Internal rotating |

|

7 |

Cooling system |

Recycled waster cooling |

|

8 |

Reactor material |

Q245R/Q345R boiler plate |

|

9 |

Heating method |

Indireact hot air heating |

|

10 |

Heating fuel |

Fuel oil/gas |

|

11 |

Feedstock |

Waste tire/plastic/rubber |

|

12 |

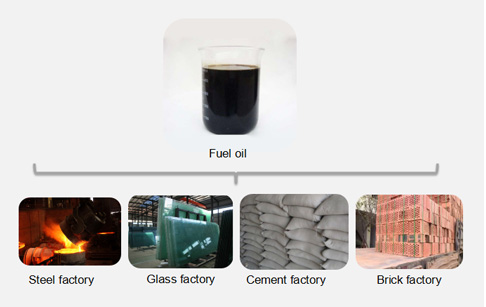

Output |

Fuel oil, carbon black |

WhatsApp

WhatsApp