Manufacturers fully automatic waste tyre pyrolysis plant

Through continuous improvement and constant technology upgrading, Doing have designed the fully automatic waste tyre pyrolysis plant which can convert tyre into useful resources more efficiently. This pyrolysis planti nclude DY-30, DY-50 and DY-50 and the daily processing capacities range from 30 to 50 tons.

The main feature of this fully automatic fully waste tyre pyrolysis plants is that they can work continuously for 24 hours per day without a stop.

Waste tyre

As the vehicle increasing with the improving living standard, more and more waste tyres generated every day. And waste tyres as a solid waste not only occupy the land, the most important is it cause pollution to the environment. So how to dispose the waste tyres becoming more and more necessary. That’s why we developed the fully automatic waste tyre pyrolysis plant

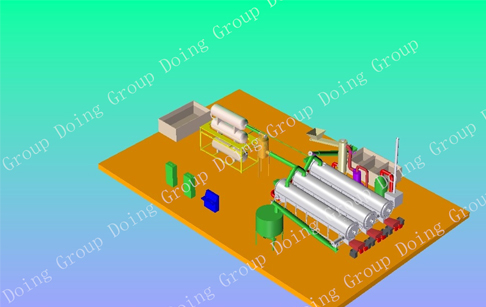

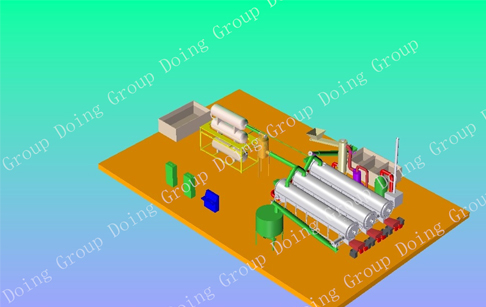

Manufacturers fully automatic waste tyre pyrolysis plant 3 D picture

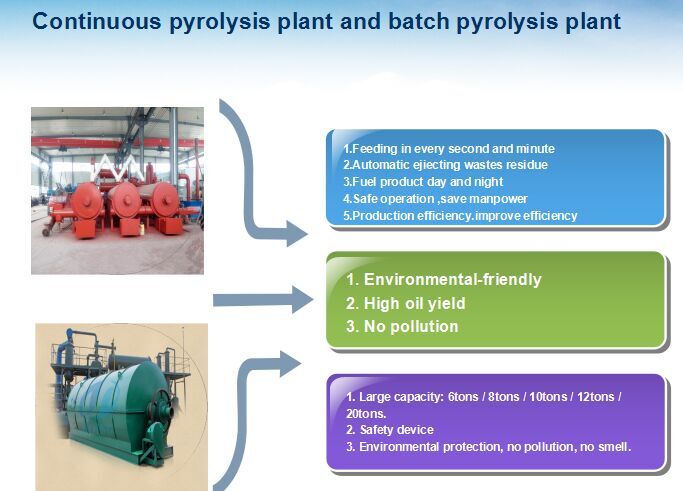

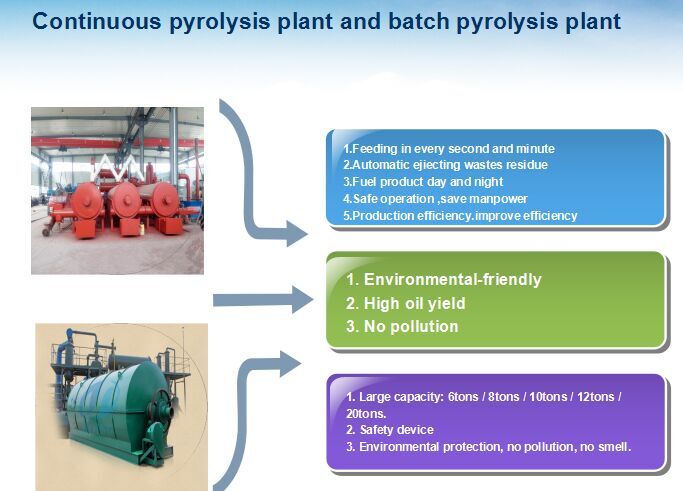

Batch pyrolysis plant can fully automatic waste tyre pyrolysis plant

But at first the fully automatic waste tyre pyrolysis plant is batch type, which has low automation and mainly operated by labour. This batch type pyrolysis plant needs to be stopped after every process for discharge residues (carbon black and steel wire) and feeding tires again. For one complete process, it takes about 16-20 hours, almost one whole day. And this batch type pyrolysis plant cannot process big quantity feedstock. For safety consideration, it only can process at most tons tyres per day. This is enough for the personal business. But for large scale waste tyre dealing companies or government projects, this kind of batch type fully automatic waste tyre pyrolysis plant may not meet their demand. So, as the increasing demand of the market and imprving technology, last year we just developed a new design as Manufacturers fully automatic waste tyre pyrolysis plant.

Manufacturers fully automatic waste tyre pyrolysis plant technical data

|

No. |

Item |

Specifications |

|

1 |

Model |

DY-C-10 |

DY-C-20 |

DY-C-30 |

DY-C-50 |

DY-C-60 |

DY-C-80 |

DY-C-100 |

|

2 |

Cpacity |

10T/D |

20T/D |

30T/D |

50T/D |

60T/D |

80T/D |

100T/D |

|

3 |

Power |

35Kw |

50Kw |

65Kw |

80Kw |

90Kw |

105Kw |

120Kw |

|

4 |

Working type |

Continuous |

|

5 |

Reactor deisgn |

Mutiple reactors (The quantity and size depends on the raw material condition) |

|

6 |

Rotating |

Internal rotating |

|

7 |

Cooling system |

Recycled waster cooling |

|

8 |

Reactor material |

Q245R/Q345R boiler plate |

|

9 |

Heating method |

Indireact hot air heating |

|

10 |

Heating fuel |

Fuel oil/gas |

|

11 |

Feedstock |

Waste tyre/plastic/rubber |

|

12 |

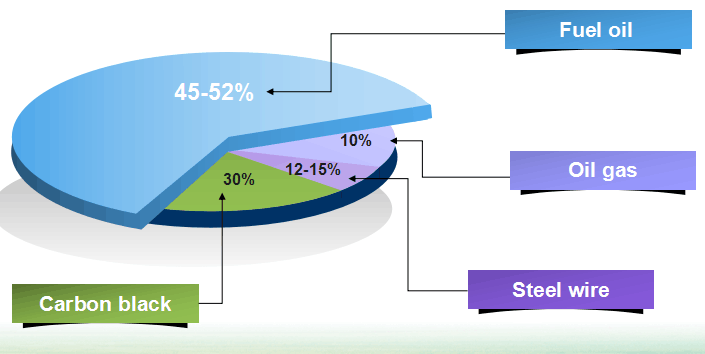

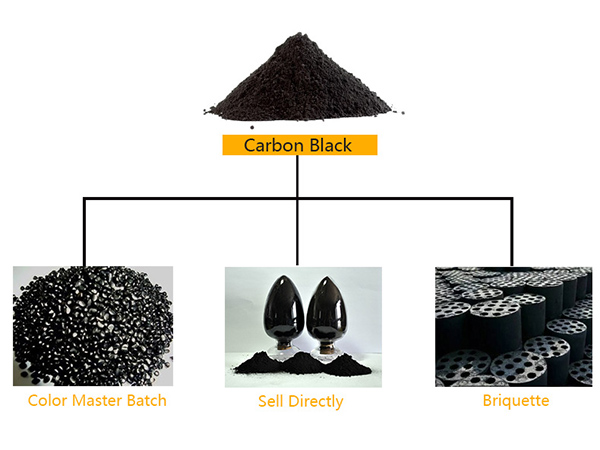

Output |

Fuel oil, carbon black |

WhatsApp

WhatsApp