Used tyre

Every year, the growing total number of private car and truck promotes development of economic all over the world; meanwhile, a large number of waste tyre has been discarded because of consumption and abrasion. Only 50% of them have been recovered, waste resources have been wasted seriously, and used tyres disposal has been focused on more and more countries, more and more people are interested in Used tyre pyrolysis process to oil plant design. It is also called as tyre pyrolysis plant.

At present, in order to meet the material performance requirements, tyres are becoming more high strength, wear resisting, stable as well as ageing resistant, which could result in tyres discarded cannot naturally degrade in much longer period, maybe hundreds of years. It is called as black pollution.

Used tyre pyrolysis process to oil plant design

Doinggroup is the top professional manufacturer of Used tyre pyrolysis process to oil plant design in China; our company has researched a suit of high-tech pyrolysis plant, which can convert waste tyre to oil in large scale, in principle of green, sustainable development and economic benefits. This plant has a great market potential. And it is also can turn waste plastic to oil.

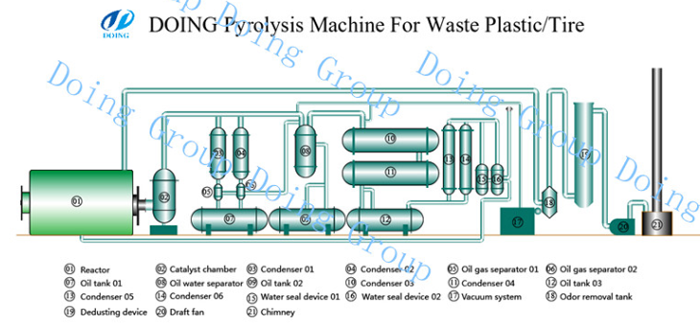

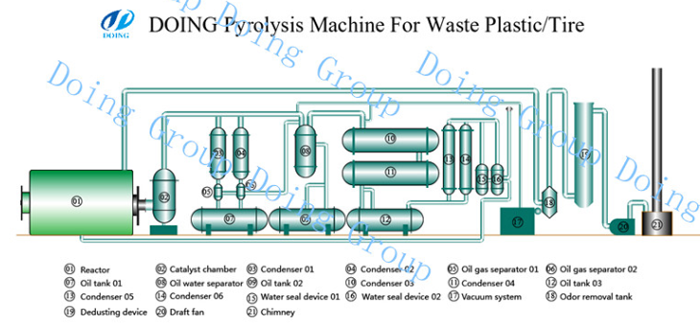

Used tyre pyrolysis process to oil plant design working process

Used tyre pyrolysis process to oil plant design working process

→ The constant temperature heating system supplies heat to the pyrolysis reactor. The raw materials are continuously fed into the pyrolysis reactor and spreaded by the system, completing pyrolysis reaction with the high-efficiency catalyst.

→ The pyrolyst oil gas is turned into high quality fuel oil and small amount of combustible gas after following processes such as fractional distillation separation, fixed bed secondary gas catalyzing and de-waxing etc.

→ The combustible gas is totally used as fuel to the system after scrubbing, which achieves heat energy self-supporting. The gas after being burnt will be qualified discharged after gas purification process.

→ The small amount of solid residue generated from the reaction is continuously discharged out of the reactor, and that could be further processed into fuel stick.

Used tyre pyrolysis process to oil plant design advantage

Used tyre pyrolysis process to oil plant design

1.Automobile industry & tyre manufacturing companies have reported high growth in recent past & is growing year by year. As a result, there is drastic growth reported in the generation of scrap tyres in recent past & will grow every year as per current survey of Tyre Asscoiation . As a result, plenty of waste tyres are available as a raw material in the market.

2. Pyrolysis Plant finished product Pyrolysis oil is in great demand in the market which is consumed & used by number of industries as a burning fuel. Pyrolysis Oil cost is cheaper than furnace oil & light deisel oil as per oil market hence, can be used as a substitute according to the various applications.

3. High raw material available & high market demand of pyrolysis plant finished products makes this business opportunity highly profitable & give return on investment within 1 year only.

Used tyre pyrolysis process to oil plant design technical data

|

Technical parameter of used tyre pyrolysis process to oil plant design |

|

No. |

Items |

Contents |

|

1 |

Equipment type |

DY-1-6 |

DY-1-8 |

DY-1-10 |

|

2 |

Raw material |

Waste tyres |

waste tyres |

waste tyres |

|

3 |

Structural form |

Horizontal rotation |

Horizontal rotation |

Horizontal rotation |

|

4 |

24-hour Capacity |

6 ton |

8 ton |

10 ton |

|

5 |

Oil yield |

2.7-3.3ton |

3.6 -4.4ton |

4.5 -5.5ton |

|

6 |

Operating pressure |

Normal |

Normal |

Normal |

|

7 |

Material of pyrolysis Reactor |

Q245R |

Q245R |

Q245R |

|

8 |

Thickness of pyrolysis Reactor |

16mm |

16mm |

16mm |

|

9 |

Rotate speed of pyrolysis Reactor |

0.4turn/minute |

0.4turn/minute |

0.4turn/minute |

|

10 |

Total power |

19KW |

19KW |

19KW |

|

11 |

Mode of cooling |

Water cooling |

Water cooling |

Water cooling |

|

12 |

Cooling area of condenser |

100sqm |

100sqm |

100sqm |

|

13 |

Kind of transmission |

Internal gear drive |

Internal gear drive |

Internal gear drive |

|

14 |

Noise dB(A) |

≤85 |

≤85 |

≤85 |

|

15 |

Size of Reactor(D×L) |

2200×6000 |

2200×6600 |

2600×6600 |

|

16 |

Working form |

Intermittent operation |

Intermittent operation |

Intermittent operation |

|

17 |

Delivery time |

20days |

20days |

20days |

|

18 |

Weight |

27T |

30T |

35T |

|

Prepared by customer about used tyre pyrolysis process to oil plant design |

|

No. |

Item |

Consumption |

|

1 |

Coal(for choice) |

500kg/day |

|

2 |

Wood(for choice) |

800kg/day |

|

3 |

Natural gas(for choice) |

100-150kg/day |

|

4 |

Oil(for choice) |

300-350kg/day |

|

5 |

Electricity |

244kwh/day |

|

6 |

Water(recycled) |

60㎥ /month |

|

7 |

Total power |

19kw |

|

8 |

Land area |

35m*15m |

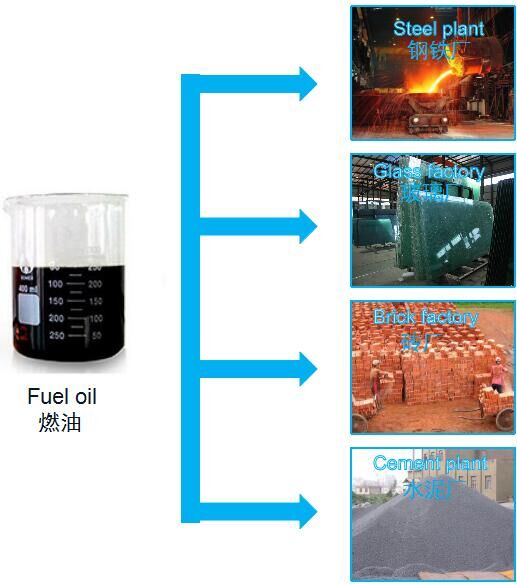

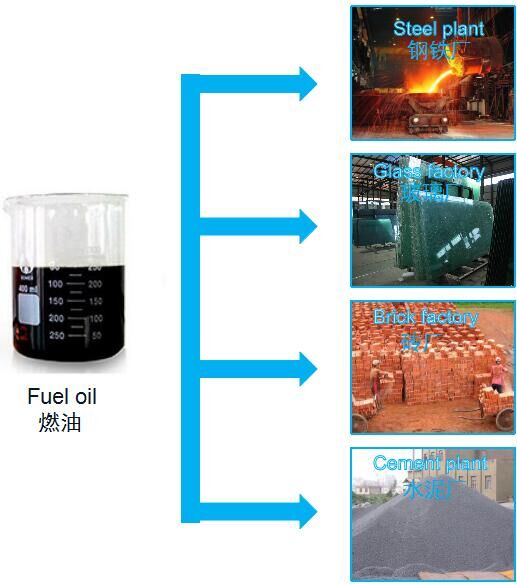

Used tyre pyrolysis process to oil plant design application

Fuel oil application

1.The usage of final production-----Fueloil

Fuel oil from tyre recycling use of used tyre pyrolysis process to oil plant design are used in below industries

A.Power plant factory

B.Plass factory

C.Cement factory

D.Ceramic factory

E.Aluminum factory

F.Boiler factory

G.Central heating factory

H.Painting factory

The usage of final production-----Carbon black

Carbon black application

Carbon black from tyre recycling use of used tyre pyrolysis process to oil plant design are used in below industries

A.Electric cable jacketing

B.Conveyor ban

C.Hose and doormat

D.Black nylon bag

E.Rubber additive

F.Automatic spare parts

G.Heat isolation

H.Black colorant in rubber materials

WhatsApp

WhatsApp