Tyre pyrolysis plant

Under the concept of green, environmental protection, and sustainable development, the tire-to-oil recycling process uses high temperature pyrolysis to turn waste tires into useful alternatives. It is a chemical process that cracks macromolecular compounds into small molecular tire oils. The complete tire recovery process is also referred to as the cracking process, through which fuel, carbon black, steel wires and combustible gases can be obtained.

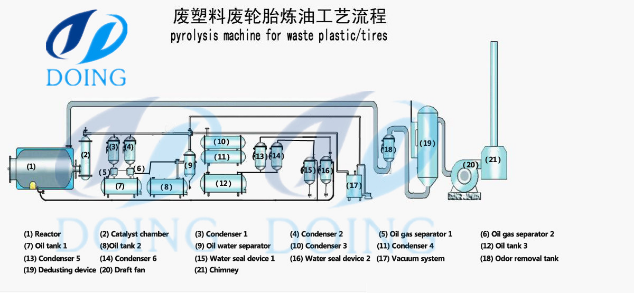

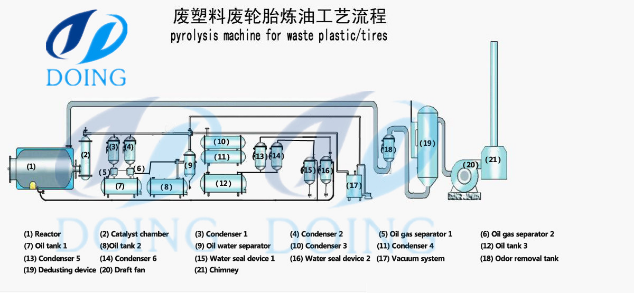

Tyre to oil recycling process

1. Collect waste tires. If possible, you can use the tire spinning machine to extract the steel wire from the waste tires. Of course, you can also put the prepared waste tire directly into the reactor.

2. The prepared waste tires, or waste tires withdrawn from the steel wire, are sent to the reaction tank through an automatic pushing device. Soldiers heated the reactor. When the temperature reaches a certain height, oil and gas will be cracked.

3. Under the effect of high and low pressure in the equipment, the cracked oil and gas enters the condensing system and is liquefied into heavy oil and flows into the oil tank. The DoingGroup adopts a three-stage condensing system to ensure that the oil and gas are cooled sufficiently to increase the oil yield.

4. Deodorize and deodorize the heavy oil in the tank and get the final fuel. In order to avoid environmental pollution caused by the discharge of poisonous and odorous gases, DoingGroup launched a desulfurization and deodorization tower system, which completely solved the problem of odor produced after the equipment was operated.

5. The carbon black produced during the combustion process will pass through the underground sealed slag discharge channel and be discharged outside the furnace. This will ensure that the discharged carbon black will not fly and pollute the air.

From the waste tire to oil process, we can finally get 45-50% fuel, 30% carbon black, 15% waste steel wire, and 5% combustible gas. Their purpose is as follows:

Tyre to oil application

Tyre to oil application

Fuel oil: Fuel oil is widely used in ship boiler fuels, furnace fuels, metallurgical furnaces, and other industrial furnace fuels. According to use, fuel oil can be divided into marine fuel oil, furnace fuel oil and other fuel oils. According to statistics from the National Bureau of Statistics, China's fuel oil consumption is mainly concentrated in power generation, transportation, metallurgy, chemical industry, light industry and other industries.

Carbon black application

Carbon black application

Carbon black: It is mainly used for pressure ball combustion and refined milling. Refined flour can be used for new tyres, rubber soles and pigments.

Steel wire application

Steel wire application

Steel wire: It can be sent to a recycling station where it can be recycled or it can be recast.

Combustible gas: It will be recycled by the equipment and used for the heating fuel of the reactor, which is energy-saving and environmentally friendly.

The DoingGroup's waste tire to oil pyrolysis plant has the following advantages:

DoingGroup's pyrolysis plant

1. The reactor is made of Q245R standard boiler plate steel. The thickness of this steel is 16mm; the arc-shaped compression head has strong compression resistance.

2. The welding adopts a unique 3-step welding process. This welding process is more detailed than ordinary welding, so it can guarantee a long service life.

3. Equipped with oil-water separator, water seal, vacuum device and other safety devices.

4. The most advanced and effective condenser in the oil industry can ensure sufficient cooling of oil and gas and high oil yield.

If you have investment needs in this equipment, please click on the link to know more , we have a professional team of engineers, will design for you based on your needs, and we provide on-site guidance installation, and equipment operation test service! !

From the waste tire to oil process, we can finally get 45-50% fuel, 30% carbon black, 15% waste steel wire, and 5% combustible gas. Their purpose is as follows:

Fuel: Fuel oil is widely used in ship boiler fuels, furnace fuels, metallurgical furnaces, and other industrial furnace fuels. According to use, fuel oil can be divided into marine fuel oil, furnace fuel oil and other fuel oils. According to statistics from the National Bureau of Statistics, China's fuel oil consumption is mainly concentrated in power generation, transportation, metallurgy, chemical industry, light industry and other industries.

Carbon black: It is mainly used for pressure ball combustion and refined milling. Refined flour can be used for new tyres, rubber soles and pigments.

Steel wire: It can be sent to a recycling station where it can be recycled or it can be recast.

Combustible gas: It will be recycled by the equipment and used for the heating fuel of the reactor, which is energy-saving and environmentally friendly.

WhatsApp

WhatsApp